PU Roller Manufacturer in India for Industrial Applications

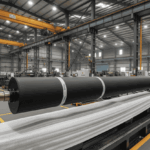

Looking for a reliable PU Roller Manufacturer in India for printing, packaging, textile, paper, steel or conveyor handling systems? Siva Rollers is a trusted polyurethane rollers manufacturer with custom-engineered PU rollers designed for high load, abrasion resistance, oil-chemical resistance and long service life. As one of the leading PU roller suppliers in India, we provide PU coated rollers, PU conveyor rollers, PU idler rollers and cast polyurethane rollers for heavy-duty industrial machinery. Our advanced polyurethane formulations deliver longer roller life, reduced downtime, and lower overall maintenance cost compared to rubber or plastic rollers.

Modern plants across India are rapidly shifting towards advanced polyurethane solutions, and that’s why choosing the right PU Roller Manufacturer & Supplier in India decides your production efficiency.

Traditional plastic rollers simply cannot handle the extreme demands of modern production environments, especially the harsh conditions found in industries like steel, textile, paper, and material handling. They wear down quickly, crack under high pressure, and demand constant, expensive replacement. This cycle of failure, replacement, and downtime is the silent killer of your bottom line.

It’s time to move beyond temporary fixes and invest in a permanent, high-performance solution that guarantees endurance and reliability. The answer lies in specialized Polyurethane Roller Manufacturer products. This decision is not just about buying a component; it’s about making a strategic investment in the efficiency and longevity of your entire operational setup.

Why Polyurethane (PU) is the Smartest Industrial Investment

Polyurethane (PU) is not just a material; it’s an engineering solution. The superior elastomeric properties of PU rollers make them fundamentally different from conventional alternatives. They offer a unique combination of toughness, resilience, and elasticity that translates directly into massive operational advantages for your plant.

When you choose a high-quality PU Roller Manufacturer in India like Siva Roller, you are choosing unmatched performance:

- Superior Abrasion Resistance: PU rollers can withstand constant friction and scraping without wearing out, dramatically extending their service life.

- High Load-Bearing Capacity: Need rollers for heavy-duty applications? PU’s chemical structure allows it to distribute weight evenly, making them the perfect High Load Bearing PU Rollers for handling massive materials without permanent deformation or failure.

- Chemical and Oil Resistance: PU remains stable when exposed to oils, greases, solvents, and various industrial chemicals, ensuring performance even in challenging, messy environments.

- Noise Reduction: Their inherent elasticity helps absorb operational vibrations and shocks, leading to a quieter, smoother, and safer working environment.

By switching to Industrial PU Roller Manufacturer products, you immediately cut down on maintenance labour and material costs, turning a depreciating asset into a durable performance tool.

Finding the Best PU Roller Supplier in India: Location and Expertise Matters

When sourcing these critical components, quality consistency is paramount. You need a partner who combines world-class manufacturing standards with local accessibility.

Siva Roller, proudly located in the industrial heartland of Ahmedabad, Gujarat, is rapidly establishing itself as the Best PU Rollers India has to offer. Our strategic location gives us the advantage of understanding the specific industrial needs of the region while serving clients nationwide.

As a dedicated PU Roller Supplier in India, we focus exclusively on polyurethane technology. This specialization means we are not generalists; we are experts in crafting custom formulations and achieving the precise hardness (Durometer) required for your unique application, be it high-speed printing or heavy-duty logistics.

Our commitment to superior materials and precision casting ensures that every single roller leaving our Ahmedabad facility meets international quality benchmarks for resilience, durability, and operational stability. For buyers focused on reliable supply chains and consistent quality, choosing a local leader in Ahmedabad provides unmatched security and speed.

Specialized Rollers for Specialized Applications

No two industrial applications are exactly alike. That’s why Siva Roller provides a full spectrum of polyurethane solutions, ensuring every stage of your production line is optimized. When evaluating your needs, consider the specific function each roller performs:

The Backbone of Logistics: PU Conveyor Rollers

For material handling and logistics operations, roller reliability is everything. Frequent replacements of conveyor rollers cause critical choke points. As a leading PU Conveyor Rollers Manufacturer India, Siva Roller produces components designed to operate continuously under the demanding conditions of distribution centres, assembly lines, and bulk processing plants. Our rollers minimise product slippage and wear, keeping your flow smooth and consistent.

Guiding the Way: PU Idler Rollers

PU Idler Rollers are vital for supporting and shaping the conveyor belt and managing belt sag across long spans. Using PU for idler rollers prevents common issues like sticking and material build-up, which can lead to belt misalignment and premature bearing failure. The durability of our PU Idler Rollers ensures long-term stability for your entire conveyor system.

Custom Surfaces and Protection: PU Coated Rollers

Sometimes, you need the strength of a metal core combined with the grip and protection of polyurethane. PU Coated Rollers are the ideal solution for printing presses, laminating machines, and various processing lines where surface protection and controlled friction are necessary. We strip old, worn coatings and apply a fresh, resilient layer of custom-spec PU, bringing old cores back to life and optimising surface performance for specific tasks like high-speed feeding or tension control.

The Power of Precision: Cast Polyurethane Rollers

For demanding, critical applications where failure is not an option—such as steel mill equipment, heavy packaging machinery, or large gantry systems—you need the density and purity of Cast Polyurethane Rollers. This manufacturing method ensures the highest possible load capacity and minimal internal flaws, delivering a component with maximum strength, ideal for precision movements and continuous heavy loads.

Understanding PU Rollers Price in India: Quality is Always Cheaper

We understand that purchasing managers must look closely at the PU Rollers Price in India. It’s easy to be tempted by a lower upfront cost from a subpar manufacturer. However, the true cost of a roller is calculated over its lifespan, not just the initial purchase price.

Consider this:

Component Type | Initial Cost (Relative) | Replacement Frequency | Total Cost of Ownership (TCO) |

Low-Grade Plastic | Low | High (Every 3-6 Months) | Very High (Downtime + Labour + Parts) |

Siva Roller (PU) | Moderate | Low (Every 2-5 Years) | Low (Maximum Uptime + Minimal Labour) |

Choosing an inferior product might save you 10% on the purchase price, but it can cost you hundreds of times that amount in lost production during unexpected failures.

Siva Roller provides high-value solutions. Our focus is on maximizing your return on investment (ROI) by delivering rollers that survive where others fail. Our custom fabrication services also allow us to create bespoke components that fit your machine perfectly, eliminating the wear caused by poorly fitted standard parts. Investing in the Best PU Rollers India has access to is a clear path to long-term profitability.

A Partner Focused on Your Success

For industrial buyers, trust, quality, and a commitment to delivery schedules are non-negotiable. Siva Roller prides itself on being more than just a PU Roller Manufacturer in India; we are a dedicated supply partner.

Our deep-rooted presence in Ahmedabad, Gujarat, means we offer fast consultation and rapid turnaround times for both custom orders and standard components across the entire country. We take your operational challenges and convert them into durable, reliable polyurethane solutions. Whether you need custom-sized Cast Polyurethane Rollers for a new line or consistent supply of PU Conveyor Rollers, we manage the complexity so you can focus on production targets.

Stop dealing with the endless cycle of roller failure. It’s time to equip your plant with components built for the future of Indian industry.

Take the Next Step Towards Optimized Production

Don’t let subpar rollers be the weak link in your operation. Contact the experts at Siva Roller today to discuss your specific requirements for PU Coated Rollers, PU Idler Rollers, or any other high-performance polyurethane component.

Let us show you how investing in quality manufacturing in Ahmedabad, Gujarat, translates into better efficiency and higher profits for your business nationwide.

Get Your Custom PU Roller Solution Today

Whether you need a PU Roller, Polyurethane Roller, or Abrasion-Resistant Extrusion Roller, Siva Rollers can design, manufacture, and deliver the perfect solution for your plant.

Contact Siva Rollers — India’s leading PU-Coated Roller Manufacturer & Supplier in India

📞 Get a Free Quotation and expert consultation for your extrusion line needs.

Contact US :

FAQs

A PU roller is used for conveying, guiding, pressing, feeding, and absorbing vibrations in machines across printing, packaging, textile, paper, steel, and logistics industries. Its durability makes it ideal for high-load and continuous operations.

Siva Rollers is widely chosen for PU rollers in India due to precision polyurethane casting, custom hardness options, long-lasting performance, and fast nationwide supply.

PU roller price depends on size, hardness, metal core type, coating thickness, load capacity, and application requirements. High-quality PU generally reduces long-term maintenance costs.

Yes. PU rollers can be customized for hardness, diameter, surface texture, chemical resistance, and load-bearing capacity to match the exact requirements of your equipment.

Yes. Polyurethane performs reliably in heat, moisture, oils, solvents, and harsh industrial chemicals, making it suitable for demanding environments.

In normal industrial conditions, a PU roller lasts 2 to 5 years, depending on load, speed, maintenance, and operating environment. This is significantly longer than standard rubber rollers.

Yes. Siva Rollers manufactures PU coated rollers, PU conveyor rollers, PU idler rollers, and cast polyurethane rollers customised for printing, packaging, and heavy-duty operations.