How the Right Rubber Roller Manufacturer Can Transform Your Manufacturing Output

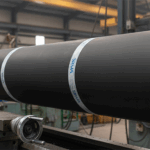

Every successful manufacturing process — whether printing, textile, paper, or packaging — depends on one silent hero: the rubber roller. These cylindrical components might look simple, but they directly influence print quality, tension control, coating uniformity, and even machine lifespan.

Yet, many industries underestimate how much the right roller impacts production efficiency. The difference between an average and a precision-engineered Industrial Rubber Roller can mean the difference between consistent output and costly downtime.

And that’s where the choice of a trusted Rubber Roller Manufacturer in Ahmedabad becomes mission-critical.

The Science Behind Industrial Rubber Rollers: What Makes Them Perform

Rubber rollers are engineered to transfer, press, or convey materials under extreme industrial conditions. The performance of industrial rubber coated rollers depends on four major factors:

- Base Material (Core) – Typically made from mild steel, aluminum, or stainless steel. The balance, straightness, and dynamic concentricity of the core determine how evenly pressure is applied across the roller.

- Rubber Compound – The outer layer can be made from natural rubber, nitrile (NBR), EPDM, neoprene, or polyurethane, depending on temperature, chemical resistance, and friction requirements.

- Coating and Hardness – Hardness (measured in Shore A) defines how the roller interacts with material. For instance, printing rollers demand uniform hardness for perfect ink transfer, while textile rollers may require softer surfaces for fabric grip.

- Precision Grinding and Finishing – Even a microscopic deviation can cause misalignment and uneven wear. High-quality rubber coated rollers manufacturer use CNC-based finishing for perfect balance and surface finish.

In short, an industrial roller isn’t just a part—it’s a calibrated instrument designed for consistent performance.

How the Right Rubber Roller Manufacturer in Ahmedabad Impacts Your Output

Ahmedabad isn’t just an industrial hub—it’s the manufacturing capital where rubber roller innovation meets application excellence. But not every manufacturer offers the same level of expertise or quality assurance.

A competent rubber roller manufacturer in India follows a scientific process:

- Customized Roller Design based on application load, speed, and surface requirements.

- Precision Balancing to reduce machine vibration and wear.

- Premium Coating Quality ensuring chemical, thermal, and abrasion resistance.

- On-time Supply & Support to minimize downtime.

The result? Improved line efficiency, extended roller life, and consistent product quality.

Choosing the wrong vendor, on the other hand, means unpredictable roller wear, higher maintenance costs, and frequent production interruptions — the silent killers of profit margins.

Understanding Rubber Roller Types and Their Industrial Applications

Different industries demand different roller properties. Here’s how:

Printing Rubber Roller

Used for offset, flexo, and gravure printing, these rollers demand surface precision for ink distribution and uniformity. A poorly manufactured printing roller leads to banding, ghosting, or inconsistent print density — problems that bleed money in wasted prints.

Textile Rubber Roller

Textile applications involve delicate fabrics and moisture. The roller’s elasticity and surface finish ensure grip without damage. High-quality textile rubber rollers maintain uniform pressure and resist temperature-induced swelling.

Rubber Conveyor Rollers

These are the lifeline of material handling systems. Designed for load-bearing and long operation cycles, rubber conveyor rollers must withstand abrasion, dust, and mechanical shock. The right hardness prevents slippage while maintaining smooth flow.

Industrial Rubber Coated Rollers

From laminating to coating and embossing, industrial rubber coated rollers play a role in dozens of processes. The key advantage lies in customized coatings—each designed for precision handling of paper, plastic film, or metal sheets.

Common Production Challenges — and How Premium Rubber Coated Rollers Solve Them

Problem 1: Surface Wear and Deformation

Low-grade rubber or uneven coating leads to early surface failure.

Solution: Premium rubber compounds and precision grinding ensure uniform coating thickness and longer service life.

Problem 2: Vibration and Machine Downtime

Unbalanced rollers cause vibration, damaging bearings and increasing maintenance intervals.

Solution: CNC-based balancing and dynamic calibration eliminate vibration issues.

Problem 3: Poor Print or Textile Output

Rollers that aren’t properly hardness-calibrated deliver inconsistent pressure.

Solution: Manufacturers like Siva Rollers ensure Shore hardness optimization per application — guaranteeing flawless output.

Siva Rollers – Best Rubber Roller Manufacturer in India

Based in Ahmedabad, Siva Rollers stands at the forefront of innovation and reliability in the rubber roller industry.

With decades of experience and advanced manufacturing technology, Siva Rollers designs, engineers, and supplies:

- Rubber Coated Rollers for printing, packaging, and textile industries.

- Rubber Conveyor Rollers for material handling and industrial automation.

- Custom Industrial Rubber Rollers built to match specific production needs.

Each roller undergoes rigorous testing for balance, surface finish, and chemical resistance.

Whether you’re a procurement engineer, OEM manufacturer, or maintenance head, Siva Rollers ensures superior performance and long-term savings — all at a competitive rubber roller price.

When productivity and precision matter, Siva Rollers is the name trusted across India and abroad.

The ROI of Quality: Why Choosing the Right Manufacturer Saves More Than It Costs

Many buyers focus on the initial rubber roller price—but the true cost lies in maintenance, downtime, and replacement cycles.

A premium roller may cost slightly more upfront but can last 3–5 times longer than cheap alternatives, reduce vibration-induced wear, and sustain higher operational speeds without distortion.

That’s the difference between running production continuously versus losing days to unscheduled shutdowns. In a competitive manufacturing landscape, reliability is the real ROI.

Transform Your Output with Precision-Engineered Rubber Rollers

purchase decision — it’s a productivity strategy.

From print quality to machine longevity, every part of your output depends on how well your rollers perform.

With advanced materials, exacting standards, and decades of industrial expertise, Siva Rollers helps you move beyond average results to engineered excellence.

Ready to Optimize Your Manufacturing Output?

Download our Exclusive Roller Specification Sheet or Request a Custom Quote from Siva Rollers, the most trusted Rubber Roller Manufacturer in Ahmedabad.

Enhance your production precision today — because every rotation counts.

FAQs

A rubber roller is a cylindrical component composed of a rigid core (steel, aluminum, etc.) covered with a rubber (or elastomer) layer. Its surface interacts with media—paper, fabric, film, etc.—to press, guide, transfer, or convey materials in industrial systems. The rubber cover provides grip, shock absorption, and chemical resistance, while the core ensures structural integrity.

Typical materials include natural rubber, nitrile (NBR), EPDM, neoprene, silicone, and polyurethane. Each offers a unique balance of hardness, abrasion resistance, chemical resistance, temperature stability, and elasticity. Selecting the correct compound is critical for roller performance and longevity.

You match roller specs to your process:

- Printing rollers need uniform hardness and excellent surface finish.

- Textile rollers require elasticity, stable dimension under moisture, and smooth grip.

- Conveyor rollers demand abrasion resistance, load-bearing capacity, and slippage control.

Consult with a rubber roller manufacturer in Ahmedabad (or India) to define core size, rubber compound, surface finish, and tolerance.

When manufactured and maintained properly, a premium rubber roller can last 3–5 times longer than a cheap alternative. Variables like operating speed, load, chemical exposure, and maintenance frequency will influence actual lifespan.

Prices depend on several factors:

- Core material and diameter

- Rubber compound (cost varies widely)

- Tolerance, precision grinding, balancing

- Volume (single vs bulk orders)

- After-sales support (recovery, replacement)

Thus, cost comparisons should be made not just on unit price but total cost of ownership.

Yes, one of the major advantages of rubber coated rollers is that the rubber layer can be stripped and recoated (recovered). This extends life, cuts costs, and reduces lead times for replacement.

Common causes:

- Use of incorrect rubber compound (chemical attack, swelling)

- Poor core balance or misalignment, causing vibration

- Uneven coating or poor bonding

- Inadequate maintenance (cleanliness, surface damage)

Avoid these by partnering with a trusted rubber roller manufacturer in India that implements precision finishing and quality control.

Lead times vary depending on complexity and order size, but many specialized manufacturers (especially in Ahmedabad / India) can deliver within 7–14 working days for typical orders. Recovery/recoating jobs may take slightly less.

Absolutely. The roller material must resist the chemicals, inks, solvents, or cleaning agents in your process. Wrong compatibility leads to swelling, softening, or cracking of the rubber surface. Always specify your operating environment when requesting a quote.

Tiny deviations in surface smoothness or balance can cause nonuniform pressure, vibration, and print defects. A premium industrial rubber roller is precision-ground, dynamically balanced, and tested to tight tolerances to ensure smooth, stable operation.