The Role of Rubber Coated Rollers in Modern Manufacturing

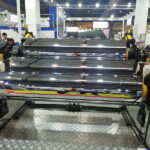

In any industrial setting — from textiles to packaging, printing to plastics — equipment performance plays a direct role in productivity and quality. Often underestimated but critically important, industrial rollers are the lifeblood of continuous manufacturing operations. Among the different types available today, hard chrome plated rollers have emerged as a preferred choice due to their outstanding mechanical strength, corrosion resistance, and precision finish.

What Are Hard Chrome Plated Rollers?

Key Benefits in Industrial and Textile Manufacturing

Enhanced Durability

The hardness of chrome plating gives these rollers a long service life, even under intense operational loads. In industries like textiles, where machines run non-stop, components need to withstand constant tension, heat, and abrasion.

Corrosion Resistance

Manufacturing processes often expose equipment to moisture, chemicals, steam, and solvents. Without proper protection, this leads to corrosion and degradation. Chrome coating acts as a barrier that resists oxidation and chemical attacks, making it ideal for wet environments and chemical processing lines.

This is especially useful in dyeing, finishing, or lamination units where rollers frequently interact with liquids.

Superior Surface Finish

A key advantage of chrome coating rollers is their micro-smooth surface, which allows for precision handling of substrates. This smoothness ensures consistent pressure and prevents surface imperfections — whether you’re dealing with delicate fabrics or flexible plastic films.

Technical Note: Surface finishes can reach as low as 0.1 µm Ra, ensuring ultra-smooth contact for sensitive materials.

Reduced Downtime

The durability and wear-resistance of chrome plated rollers mean less frequent breakdowns or surface repairs. This translates into reduced downtime — an essential metric for industries where uninterrupted production is critical.

Fewer roller changes also reduce labor costs and eliminate calibration delays, ensuring your operations stay on track.

Cost Efficiency Over Time

Though chrome plated rollers come at a premium cost compared to standard rollers, their long lifespan and minimal maintenance requirements result in a lower total cost of ownership.

Think of it this way: investing once can save you from recurring replacements and expensive downtimes. Many industries have reported 20–30% savings over a 2–3 year cycle due to the extended operational life of chrome rollers.

How Chrome Coating Rollers Improve Fabric and Material Quality

When working with high-speed or high-tension materials, surface uniformity becomes paramount. A rough or worn-out roller can cause defects like streaks, misalignment, or even tears.

Chrome coating rollers support:

- Uniform tension control

- Consistent heat transfer

- Static reduction

- Defect-free finishes

Use Cases Across Industries

While this blog emphasizes textile manufacturing, hard chrome plated rollers have proven indispensable in many sectors:

Maintenance Tips for Chrome Plated Rollers

To maintain their high performance, follow these practical maintenance guidelines:

With minimal upkeep, chrome rollers can serve reliably for several years.

Why Choose Siva Rollers for Chrome Coating Rollers?

With over two decades of experience and cutting-edge production facilities in Ahmedabad, Gujarat, we manufacture: