Top Benefits of Using Rubber Rollers in Manufacturing & Printing

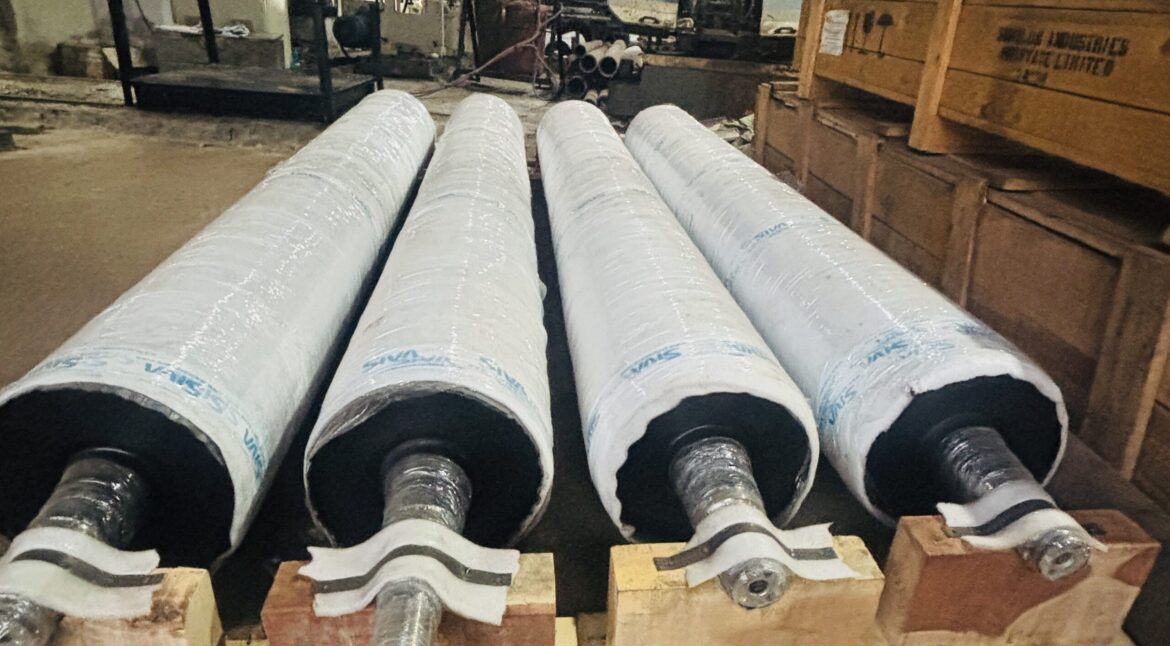

In today’s fast-paced industrial world, precision, consistency, and durability are vital to achieving high-quality output in both manufacturing and printing. Among the many components that contribute to seamless operations, the rubber roller stands out as a powerhouse of performance and versatility. Whether in textile mills, packaging units, or offset printing machines, rubber coated rollers play a silent yet critical role in improving efficiency and end-product quality.

This blog explores the top benefits of using rubber rollers in manufacturing and printing, why they’re indispensable in modern industries, and how choosing the right rubber roller manufacturer in India can transform your production line.

Precision and Uniform Pressure Distribution

One of the most important features of a rubber roller is its ability to apply uniform pressure across the surface. This consistency is crucial in both manufacturing and printing applications. In printing, for example, even pressure ensures clean and sharp image transfer onto substrates. In manufacturing, it leads to consistent lamination, embossing, or coating—depending on the application.

This precision results in fewer errors, minimal waste, and higher productivity. Printing rubber rollers are specially designed to deliver smooth and even contact on the material surface, making them essential for high-speed printing lines that demand perfect registration.

Enhanced Durability in Harsh Environments

Rubber coated rollers are engineered to withstand a variety of harsh industrial conditions, including exposure to chemicals, heat, and mechanical stress. The rubber coating, depending on its formulation (like nitrile, EPDM, silicone, or natural rubber), provides resistance to oil, solvents, moisture, and even UV rays.

This resilience extends the roller’s operational life, reduces downtime for maintenance or replacement, and improves the overall reliability of the production system. Whether it’s high-temperature lamination or high-speed web handling, rubber rollers perform consistently under pressure.

Versatility Across Industries

From paper to textiles, metal processing to packaging, rubber rollers are universally adaptable. Their wide range of hardness, sizes, and surface finishes allows them to be customized for multiple uses such as printing, laminating, embossing, coating, and material guiding.

For example, in the textile industry, rubber rollers ensure wrinkle-free fabric movement, while in the steel industry, they help with tension control. This wide applicability makes rubber coated rollers a preferred choice across sectors, especially when smooth and damage-free material handling is required.

Cost-Effective and Low Maintenance

Compared to metal rollers, rubber rollers are often more affordable and require less frequent maintenance. Their ability to absorb vibration reduces machine wear and tear, thus extending the life of both the roller and the machinery it operates within.

Additionally, the surface of a rubber roller can be reground or recoated instead of replaced entirely, adding further value and reducing long-term operational costs. This recyclability makes them an eco-friendly and budget-conscious choice for businesses seeking to improve their production efficiency without recurring high expenses.

Superior Traction and Grip

In manufacturing processes that involve movement of materials—such as conveyors, laminators, and printing presses—traction is everything. Rubber rollers provide excellent grip without damaging delicate surfaces. This controlled movement ensures alignment, reduces slippage, and improves the speed and accuracy of operations.

For printing rubber rollers, this grip is critical in preventing misregistration or print defects, especially in high-speed digital or flexo printing systems. Their ability to handle various materials—paper, plastic, fabric, or metal sheets—adds another level of efficiency to the workflow.

Customizability and Surface Engineering

One of the most underrated benefits of rubber rollers is how easily they can be customized. Based on your specific industry needs, the rubber coating can be made harder or softer, rough or smooth, or chemically resistant. Custom grooving, crowned profiles, and special finishes can be added to meet exact production requirements.

A reliable rubber roller manufacturer in India like Siva Rollers provides this level of customization, enabling businesses to optimize their machinery for peak performance. Their engineering team works closely with industries to deliver tailored roller solutions that improve throughput and quality.

Smoother Printing with Minimal Ink Wastage

In the printing industry, rubber rollers play a direct role in the quality of the printed output. From ink distribution rollers to impression rollers, they ensure consistent ink flow and contact with the substrate. This minimizes wastage, avoids streaks or blotches, and allows for accurate reproduction of colors and details.

Printing rubber rollers from Siva Rollers are designed with high-precision tolerances and advanced rubber formulations to meet the demands of modern printing technology, including flexographic, gravure, and offset systems.

Noise and Vibration Reduction

Noise pollution and machinery vibration can lead to discomfort for workers and degradation of equipment over time. Rubber rollers, due to their natural damping properties, absorb vibrations and reduce operational noise.

This not only improves the working environment but also protects other sensitive machine components from excessive wear, further extending the life of the entire system.

Supporting Sustainability and Energy Efficiency

Modern industries are under increasing pressure to reduce energy consumption and operate more sustainably. Rubber coating rollers assist in this effort by minimizing slippage, which improves motor efficiency and reduces power consumption.

Furthermore, their long operational life and the option to recoat instead of replace make them a greener choice. Using rubber rollers supports circular manufacturing practices, aligning with modern ESG (Environmental, Social, Governance) goals.

Why Choose Siva Rollers – Best Rubber Rollers Manufacturer in India

When it comes to sourcing high-performance rubber rollers, choosing a trusted manufacturer is crucial. Siva Rollers stands out as the best rubber roller manufacturer in India, known for precision engineering, quality materials, and customer-focused service.

Whether you need printing rubber rollers, rubber coated rollers for laminating, or custom solutions for your industry, Siva Rollers provides:

- In-house design and testing

- Advanced rubber formulations

- Fast delivery and on-site support

- International quality compliance

With decades of experience and clients across India and abroad, Siva Rollers is the name industries trust for excellence in rubber roller technology.

Final Thoughts

The benefits of using rubber rollers in manufacturing and printing are immense. From enhanced precision and durability to cost savings and customization, these components form the backbone of efficient production systems. Their ability to perform under diverse industrial conditions makes them a smart, long-term investment for any manufacturing or printing setup.

When looking to buy or upgrade your rubber rollers, partnering with a reputed rubber roller manufacturer in India ensures you get products that are tailored to your needs, durable, and performance-driven. Choose Siva Rollers—the industry leader in rubber coated rollers and printing rubber rollers—to power your production with confidence.

FAQs

Rubber rollers offer uniform pressure, excellent grip, high durability, and resistance to harsh chemicals and temperatures. They also help reduce operational noise and vibration, making them ideal for a wide range of manufacturing applications.

In printing, rubber rollers ensure smooth ink transfer, uniform pressure on substrates, and reduced ink wastage. This results in sharper image reproduction and consistent print quality, especially in high-speed offset or flexographic printing.

Rubber coating rollers are used in industries such as printing, textile, packaging, paper, metal processing, and plastics. Their versatility makes them essential for tasks like laminating, embossing, coating, and guiding materials.

The lifespan of a rubber roller depends on the material, usage conditions, and maintenance. High-quality rubber rollers from a reliable manufacturer like Siva Rollers can last several years, especially when properly maintained or periodically recoated.

A rubber roller refers to any roller made entirely or partially from rubber, while a rubber coating roller usually has a metal or composite core covered with a rubber surface to provide grip, flexibility, and durability in specific industrial tasks

Yes, rubber rollers can be fully customized in terms of hardness (durometer), surface texture, diameter, length, and rubber formulation. Siva Rollers, a leading rubber roller manufacturer in India, offers complete customization for industrial needs.

Printing rubber rollers are used in printing machines to transfer ink, apply pressure, or guide paper and other materials. They play a critical role in ensuring clear, uniform, and high-speed printing output without defects.

You can buy top-quality rubber rollers from Siva Rollers, recognized as one of the best rubber roller manufacturers in India. They provide custom-engineered solutions for a wide range of manufacturing and printing applications.

Yes, depending on the rubber compound used (like silicone or EPDM), rubber rollers can withstand high temperatures, making them suitable for heat-based processes such as lamination or curing.

Siva Rollers offers advanced engineering, durable rubber compounds, precision finishing, and tailored solutions for various industries. Their rollers are known for high performance, long life, and consistent results across applications.