Top Benefits of Using Stainless Steel Rollers in Manufacturing

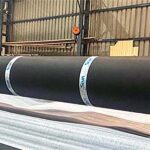

In the dynamic world of manufacturing, efficiency, durability, and precision are key to maintaining productivity and ensuring product quality. One essential component that plays a significant role in many manufacturing processes is the Stainless Steel Roller. These rollers are widely used across various industries due to their excellent properties and performance advantages. Whether in food processing, textiles, paper, packaging, or heavy engineering, stainless steel rollers prove to be a reliable choice.

Let’s explore the many benefits of using stainless steel rollers in manufacturing and understand why they are preferred over other types of industrial rollers.

Corrosion Resistance for Long-Term Performance

One of the most appreciated features of a Stainless Steel Roller is its remarkable resistance to corrosion. In manufacturing environments where moisture, chemicals, or extreme temperatures are common, ordinary rollers may degrade quickly. Stainless steel, however, resists rust and corrosion even under the harshest conditions. This makes these rollers ideal for applications like food processing, chemical handling, and outdoor machinery where exposure to water or corrosive substances is frequent.

The corrosion-resistant nature ensures a longer service life, reducing maintenance needs and replacement frequency. This leads to lower operational costs over time, making it a smart investment for manufacturing units.

High Strength and Load-Bearing Capacity

Industrial Rollers must often handle heavy loads, continuous movement, and high-speed operations. Stainless steel, known for its superior strength and rigidity, makes an excellent material choice for these demanding applications.

Stainless steel rollers can carry more weight and withstand significant pressure without deforming. This is particularly important in industries like steel manufacturing, textile machinery, or paper mills, where constant stress on rollers is the norm. The strength of stainless steel not only ensures smooth performance but also contributes to the stability of the entire system.

Smooth Surface for Consistent Output

In many manufacturing processes, especially those involving materials like films, textiles, or sheets, the surface finish of the roller plays a critical role. A Stainless Steel Guide Roller provides a smooth, polished surface that ensures uniform contact with materials. This smooth finish reduces friction, prevents sticking, and avoids unwanted marks or damage on the product being processed.

Such consistency improves product quality and ensures efficient handling of delicate materials. For example, in the printing or textile industry, even a slight imperfection in the roller surface can ruin the entire batch. Stainless steel rollers eliminate that risk.

Hygienic and Easy to Clean

In industries like pharmaceuticals and food processing, hygiene is non-negotiable. Stainless Steel Rollers are preferred in such sectors because they are non-porous and easy to clean. They don’t absorb moisture, bacteria, or odors, which helps maintain a sterile processing environment.

Cleaning is also more straightforward. These rollers can be sanitized quickly with high-pressure water, steam, or chemical solutions without the risk of corrosion or contamination. This quality makes stainless steel an industry-standard in applications that require cleanliness and product safety.

Resistance to Heat and Cold

Manufacturing often involves extreme temperatures — from baking ovens to freezing chambers. Stainless steel has a high melting point and maintains its structural integrity even under intense heat. Similarly, it does not become brittle in low-temperature environments.

Whether used in plastic molding machines or refrigeration systems, Industrial Rollers made from stainless steel perform efficiently without warping or cracking. Their thermal stability enhances safety and ensures reliable function under temperature variations.

Low Maintenance and Cost Efficiency

Due to their robust nature and resistance to various environmental factors, stainless steel rollers require minimal maintenance. Unlike rubber-coated or mild steel rollers, they do not need frequent lubrication, painting, or repairs. Their durability translates to fewer breakdowns, reduced downtime, and less need for replacements.

Over the long run, this saves both time and money for manufacturers. It also ensures continuous production without the unexpected costs associated with equipment failure or degradation.

Compatibility with Automation Systems

Modern manufacturing is rapidly moving towards automation and smart systems. Stainless steel rollers offer the precision and reliability needed for integration into automated conveyor lines, robotic arms, or precision cutting and packaging systems.

Their ability to maintain consistent speed, alignment, and load-bearing capabilities without slippage or wear makes them compatible with high-precision environments. Whether as part of a Stainless Steel Guide Roller system or a full-scale automated production line, they help streamline the entire process.

Eco-Friendly and Recyclable

In an age where sustainability is a key concern, stainless steel stands out as an environmentally friendly material. It is 100% recyclable and can be reused without losing its quality. When Stainless Steel Rollers reach the end of their life cycle, they can be recycled and remanufactured, minimizing environmental impact.

This makes stainless steel not only a practical but also a responsible choice for industries aiming to reduce their carbon footprint.

Versatility Across Industries

Rubber rollers are used in a wide array of industries due to their adaptable nature. Here are a few examples:

- Textile industry: For calendaring, dyeing, and printing processes.

- Paper industry: For coating, pressing, and conveying.

- Packaging: In lamination, sealing, and slitting machines.

- Steel and metal: Used in coating and polishing lines.

- Printing industry: In offset, flexo, and gravure presses.

This broad usability underlines the value of rubber rollers in day-to-day manufacturing and production.

Why Choose Siva Rollers?

If you are looking for high-quality, reliable Stainless Steel Rollers for your manufacturing operations, Siva Rollers is your trusted partner. Based in Ahmedabad, India, Siva Rollers is known for delivering precision-engineered rollers that meet global standards.

As a leading Stainless Steel Rollers Manufacturer in Ahmedabad, India, Siva Rollers offers unmatched quality, durable products, and excellent customer service. Whether you need custom-designed Stainless Steel Guide Rollers or robust Industrial Rollers, Siva Rollers has the expertise and infrastructure to meet your specific requirements.

Their commitment to innovation, timely delivery, and performance makes them the preferred choice for manufacturing companies across India and beyond.

Final Thoughts

The use of Stainless Steel Rollers in manufacturing brings numerous advantages — from durability and hygiene to temperature resistance and cost-effectiveness. These rollers play a vital role in ensuring smooth production, improved quality, and operational efficiency.

For businesses looking to enhance their manufacturing systems with top-quality Industrial Rollers, stainless steel is undoubtedly the right choice. And when it comes to reliable suppliers, Siva Rollers in Ahmedabad stands out for its engineering excellence and industry-leading products.