Top Problems Faced in Extrusion Cooling Rollers and Their Solutions

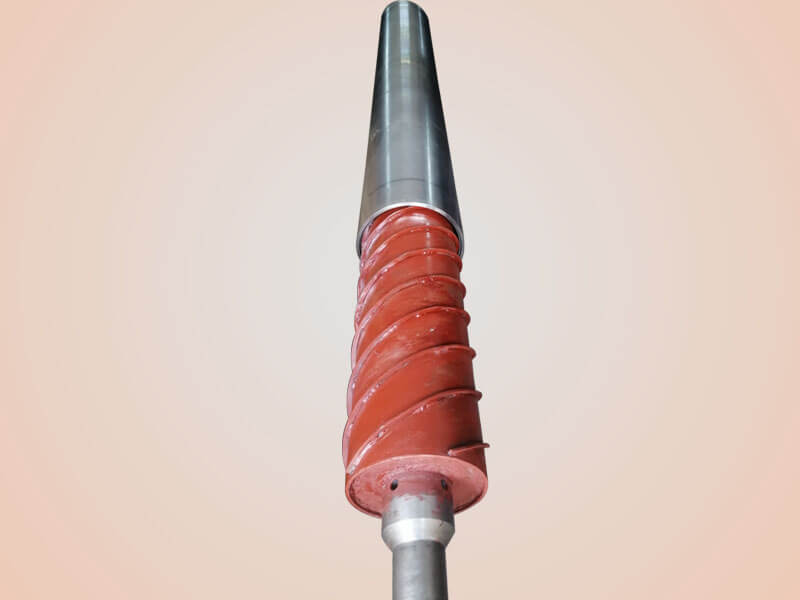

In the plastic manufacturing industry, extrusion cooling rollers play a critical role in ensuring product quality and process efficiency. From PVC sheets to plastic films, these rollers are integral to the Plastic Extrusion Process, helping to solidify and cool extruded materials quickly and uniformly. However, like any high-precision industrial equipment, extrusion cooling rollers can face a variety of challenges that affect productivity, product quality, and operational costs. Understanding these common problems and their solutions is essential for manufacturers, engineers, and industrial decision-makers seeking reliable Extrusion Line Solutions.

In this article, we’ll explore the top problems faced in extrusion cooling rollers and provide practical, actionable solutions. We will also highlight why partnering with an experienced Cooling Rollers Supplier like Siva Rollers, a trusted Extrusion Cooling Rollers Manufacturer in India, can make a significant difference in optimizing your extrusion operations.

Uneven Cooling of Plastic Sheets and Films

Problem:

One of the most frequent issues in the Plastic Sheet & Film Manufacturing process is uneven cooling. Uneven cooling can result in warping, thickness inconsistencies, surface defects, and poor dimensional accuracy of the final product. This issue often arises due to improper roller alignment, inconsistent water flow, or inadequate roller surface contact.

Solution:

- Precision Alignment: Ensure that Extrusion Line Rollers are precisely aligned. Misaligned rollers create uneven pressure and cooling patterns.

- Uniform Water Flow: Use well-maintained Water-Cooled Rollers with proper flow rates. Even a small variation in water circulation can cause hotspots.

- Surface Quality: Invest in Chrome-Plated Rollers or Heat Transfer Rollers for Plastics with smooth and defect-free surfaces for optimal contact with the extruded material.

Regular inspection and calibration can prevent uneven cooling and improve product consistency.

Roller Surface Damage and Wear

Problem:

Roller surfaces are subjected to continuous contact with molten plastics, abrasive additives, and high-speed extrusion. Over time, this can lead to scratches, pitting, or coating degradation. Damaged rollers not only reduce the efficiency of cooling but also compromise the quality of plastic sheets and films.

Solution:

- High-Quality Materials: Choose PVC Extrusion Rollers or Plastic Film Chill Rollers made from durable materials like chrome-plated steel or ebonite-coated surfaces.

- Routine Maintenance: Implement a Roller Maintenance & Troubleshooting schedule to detect early signs of wear. Polishing minor scratches can extend roller life.

- Protective Coatings: Consider applying protective coatings to Custom Extrusion Rollers to resist chemical attack and abrasion.

Investing in robust roller materials and surface treatments reduces downtime and replacement costs in the long run.

Temperature Control Issues

Problem:

Maintaining the correct temperature in the extrusion line is critical. Inconsistent temperatures in Extrusion Line Temperature Control can result in uneven cooling, sheet warping, and material stress. This issue is often caused by faulty thermostats, uneven water distribution, or inadequate heat exchange efficiency in rollers.

Solution:

- Advanced Cooling Rollers Technology: Use Industrial Rollers for Extrusion equipped with precise temperature control systems.

- Regular Inspection: Monitor water flow, inlet/outlet temperatures, and pressure in Water-Cooled Rollers.

- Upgraded Systems: Implement digital temperature controllers to maintain consistent Plastic Sheet Cooling across all rollers.

Proper temperature management ensures uniform extrusion and high-quality finished products.

Roller Misalignment and Mechanical Failures

Problem:

Misalignment or mechanical failure in extrusion rollers can lead to production inefficiencies, excessive wear, and even complete line shutdowns. Common mechanical issues include bearing failure, shaft bending, or frame distortion.

Solution:

- Precision Engineering: Opt for Custom Extrusion Rollers manufactured with high tolerances to prevent misalignment.

- Scheduled Maintenance: Conduct routine checks for bearings, shafts, and roller frames.

- Lubrication Management: Ensure proper lubrication of moving parts to reduce friction and wear.

Choosing a reputable Cooling Roller Manufacturer in India ensures reliable roller design and mechanical integrity.

Corrosion and Contamination

Problem:

In industrial environments, Plastic Cooling Rollers are often exposed to water, chemicals, and other contaminants that can cause corrosion. Corrosion not only affects cooling efficiency but can also transfer impurities to the plastic sheet or film surface.

Solution:

- Corrosion-Resistant Materials: Use Stainless Steel Cladding Rollers or Chrome-Plated Rollers for resistance against rust and chemical attack.

- Water Treatment: Implement proper water filtration and chemical treatment systems for Water-Cooled Rollers.

- Routine Cleaning: Regularly clean roller surfaces to prevent buildup and contamination.

Adopting corrosion-resistant solutions extends roller life and maintains consistent product quality.

Inadequate Roller Sizing or Design

Problem:

Improper roller diameter, width, or spacing can disrupt cooling efficiency and create tension issues in the Plastic Extrusion Process. This often happens when rollers are not matched to the specific extrusion line or plastic material.

Solution:

- Custom Roller Design: Work with a trusted Cooling Roller Manufacturer in India to design Custom Extrusion Rollers that meet your production requirements.

- Process Optimization: Conduct a thorough analysis of extrusion speed, sheet thickness, and material type to determine ideal roller specifications.

- Retrofit Solutions: Upgrade existing lines with properly sized rollers to enhance production efficiency.

A well-designed roller system ensures smooth operation and high-quality output.

Water Leakage in Cooling Rollers

Problem:

Water-Cooled Rollers are prone to leaks, especially if seals degrade or joints are improperly fitted. Leakage can cause downtime, damage electrical components, and reduce cooling efficiency.

Solution:

- High-Quality Seals: Use durable seals and gaskets in all Industrial Extrusion Equipment.

- Leak Detection: Implement routine inspection and monitoring systems to detect early signs of leakage.

- Professional Installation: Ensure rollers are installed by experienced technicians to minimize risk.

Preventing water leakage protects both equipment and product quality.

Why Choosing a Trusted Supplier Matters

Selecting the right Cooling Rollers Supplier is as crucial as choosing the right roller technology. An experienced supplier ensures:

- Superior product design and material selection

- Customization according to extrusion line requirements

- Long-term support, maintenance guidance, and troubleshooting assistance

- Access to the latest Cooling Rollers Technology for plastics

Siva Rollers, a leading Extrusion Cooling Rollers Manufacturer & Supplier in India, offers high-performance Extrusion Line Rollers, including PVC Extrusion Rollers, Plastic Film Chill Rollers, Heat Transfer Rollers for Plastics, and Water-Cooled Rollers. With decades of experience serving the Plastic Sheet & Film Manufacturing industry, Siva Rollers combines precision engineering with tailored solutions for every extrusion line.

Final Thoughts

Extrusion cooling rollers are vital to the success of any plastic manufacturing operation. From uneven cooling and roller wear to temperature control and mechanical failures, the challenges are diverse but manageable with the right approach. Implementing Roller Maintenance & Troubleshooting, choosing corrosion-resistant materials, and leveraging advanced Cooling Rollers Technology can significantly improve productivity and product quality.

Partnering with an experienced Cooling Roller Manufacturer in India like Siva Rollers ensures access to high-quality Custom Extrusion Rollers, Chrome-Plated Rollers, PVC Extrusion Rollers, and Water-Cooled Rollers tailored to your Plastic Extrusion Process. With expert guidance, precision engineering, and industry-leading support, you can optimize your Extrusion Line Solutions and achieve consistent, high-quality results.

For reliable Plastic Cooling Rollers, expert consultation, and Industrial Extrusion Equipment solutions, reach out to Siva Rollers today and elevate your extrusion operations with trusted expertise.

FAQs

Extrusion cooling rollers are used to cool and solidify plastic sheets and films in the Plastic Extrusion Process, ensuring product consistency and quality.

Common reasons include uneven cooling, roller wear, mechanical misalignment, temperature inconsistencies, and corrosion. Proper maintenance and high-quality rollers mitigate these issues.

Ensure precise roller alignment, uniform water flow in Water-Cooled Rollers, and high-quality roller surfaces, such as Chrome-Plated Rollers or Heat Transfer Rollers for Plastics.

Durable materials like chrome-plated steel, stainless steel, and ebonite-coated surfaces resist wear, corrosion, and chemical damage.

Siva Rollers is a trusted Cooling Roller Manufacturer & Supplier in India, offering custom Plastic Cooling Rollers, PVC Extrusion Rollers, and expert support for industrial extrusion lines.