Trusted Hard Chrome Plating Roller Manufacturer in India – Enquire Now

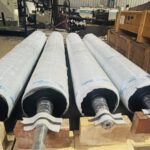

In the world of modern manufacturing, chrome plating rollers are vital components that define the efficiency and precision of industrial machinery. Whether in packaging, printing, plastic processing, or converting industries, chrome rollers play a critical role in ensuring smooth operation, durability, and enhanced surface quality. India has emerged as a leading hub for producing high-grade industrial rollers, with manufacturers like Siva Rollers setting the benchmark for quality and innovation. If you are looking for a trusted hard chrome plating roller manufacturer in India, this blog will guide you through everything you need to know before making a purchase.

What is a Chrome Coating Roller?

A chrome coating roller, often referred to as a chrome plated roller or hard chrome roller, is a type of industrial roller that features a layer of hard chromium deposited on its surface. The process, known as hard chrome plating, enhances the roller’s surface with increased hardness, wear resistance, corrosion resistance, and a mirror-like finish. These features are especially important in high-speed machinery where minimal friction and high performance are critical.

The chrome coating roller is typically manufactured using high-strength steel or alloy bases, followed by a series of grinding, polishing, and electroplating processes. The final outcome is a chrome coated roller that can handle extreme pressures, resist chemical wear, and maintain its dimensional integrity under heavy-duty use.

Applications of Chrome Rollers in Industry

Industrial roller with chrome plating are widely used across various industries due to their unmatched surface quality and durability. From packaging lines to film manufacturing units, these rollers ensure the highest level of precision and consistency.

In the printing industry, chrome plated rollers are used to ensure clean, crisp image transfers by maintaining uniform ink flow and pressure. In plastic and extrusion lines, chrome rollers play a key role in cooling and shaping materials during the production process. Similarly, in textile machinery, these rollers reduce friction and enhance the speed of fabric movement.

Because of their versatility, chrome rollers are indispensable in sectors such as:

- Packaging and lamination

- Paper and pulp manufacturing

- Film and foil converting

- Textile and fabric production

- Steel and aluminum rolling mills

- Plastic and rubber extrusion

Benefits of Using Chrome Coated Rollers

Choosing a chrome coated roller brings a range of benefits that directly impact the quality of the production process. The hard chrome surface offers a higher degree of surface hardness, typically around 65-70 HRC (Rockwell Hardness Scale), which helps reduce wear and tear even under continuous operation.

One of the most important advantages of a chrome roller is its exceptional corrosion resistance. This makes it ideal for environments where humidity, chemicals, or temperature fluctuations are common. The roller’s ability to maintain its surface characteristics over time results in longer service life and reduced maintenance costs.

Additionally, the mirror finish achieved through polishing allows better material handling and reduces surface friction, leading to smoother processing lines and less wastage. The dimensional accuracy of chrome rollers also ensures consistent product quality, making them an essential part of precision-based manufacturing.

Importance of a Trusted Manufacturer

While many companies may offer chrome coating rollers, it is crucial to partner with a manufacturer that upholds international quality standards and offers tailored solutions. A reputable chrome roller manufacturer not only ensures high-grade material usage but also implements strict inspection protocols, advanced plating techniques, and efficient post-processing methods.

Working with a trusted hard chrome plating roller manufacturer in India ensures you receive products that are engineered for reliability, surface integrity, and mechanical excellence. From custom sizing to enhanced coatings, a professional manufacturer understands the technical requirements of different industries and provides solutions that align with your specific operations.

Why Choose Siva Rollers for Chrome Coating Rollers?

If you’re looking for a manufacturer you can trust, Siva Rollers stands out as the best hard chrome plating roller manufacturer in Ahmedabad, India. With years of experience in the field, Siva Rollers has become synonymous with quality, innovation, and precision in the industrial roller segment.

Siva Rollers specializes in the production of:

- Chrome Coating Rollers

- Hard Chrome Plated Rollers

- Rubber and PU Coated Rollers

- Ebonite Rollers

- Cooling and Heating Rollers

- Anti-deflection and Bow Rollers

The company utilizes cutting-edge electroplating equipment and grinding technology to ensure that every chrome coated roller meets the required standards of hardness, finish, and dimensional accuracy. Their rollers are tested under stringent quality control protocols before they are dispatched to clients across India and international markets.

Siva Rollers also offers end-to-end support, including consultation, custom design, repair, and re-coating services. Whether you’re in packaging, printing, or plastic manufacturing, Siva Rollers delivers robust solutions built to perform in the toughest industrial environments.

Things to Consider Before Ordering a Chrome Roller

Before placing an order for a hard chrome coating roller, it is essential to assess your requirements in detail. Consider factors such as:

- Roller diameter and length to match your machinery

- Load capacity and operating speed

- Surface finish required (mirror, matte, textured)

- Base material (Mild Steel, Stainless Steel, etc.)

- Environmental exposure (chemicals, temperature, moisture)

Working with a manufacturer like Siva Rollers helps streamline this process. Their technical team can assist with selecting the ideal roller specifications to ensure maximum productivity and minimal downtime.

Enquire Now for the Best Chrome Coated Rollers in India

Whether you are setting up a new production line or upgrading your existing machinery, investing in chrome plated rollers from a trusted manufacturer ensures long-term returns. With proven performance across various industries, chrome rollers offer reliability, durability, and operational efficiency.

Don’t compromise on quality when your production depends on it. Choose Siva Rollers, the leading hard chrome plating roller manufacturer in Ahmedabad, India, for reliable and cost-effective industrial roller solutions.

You can easily enquire now by contacting Siva Rollers through their official website, email, or phone. Their dedicated customer support team ensures prompt responses and detailed quotations based on your industrial needs.

FAQs

A hard chrome coating roller is an industrial roller with a surface layer of hard chromium applied through electroplating. This coating improves surface hardness, corrosion resistance, and wear resistance, making it ideal for use in high-speed and high-pressure industrial environments.

Chrome coated rollers are commonly used in industries like printing, packaging, plastic film extrusion, paper manufacturing, textiles, and metal processing, where high-precision and low-friction rollers are essential.

The lifespan of a hard chrome roller depends on the application and operating environment, but typically, they last several years under proper maintenance, due to their extreme hardness and wear resistance.

Hard chrome coatings generally have a surface hardness of 65–70 HRC (Rockwell Hardness Scale), which significantly improves the roller's durability and resistance to mechanical wear.

Yes, hard chrome rollers can often be refurbished by grinding down the worn surface and reapplying a fresh layer of hard chrome, making them cost-effective for long-term use.

Benefits include improved wear resistance, better corrosion protection, high surface smoothness, low coefficient of friction, and extended roller life, all of which enhance production efficiency.

You should consider factors such as roller dimensions, load capacity, surface finish, operating speed, and exposure to chemicals or temperature. A trusted manufacturer like Siva Rollers can help with technical selection based on your machinery and application.

Chrome plated rollers offer superior hardness and chemical resistance compared to rubber, PU, or Teflon coatings. They are ideal for applications requiring high tolerance and low friction performance.

Yes, hard chrome coating can withstand high operating temperatures and is often used in environments where thermal stability is important, such as in plastic and metal extrusion.

You can buy high-quality hard chrome rollers from Siva Rollers, a leading manufacturer based in Ahmedabad, Gujarat, India. They provide custom solutions for chrome coated rollers across multiple industries.