Trusted Heat Transfer Roller Manufacturer for Consistent Heating & Zero Surface Damage

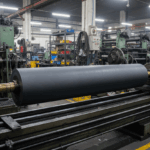

In the fast-paced world of Indian manufacturing—from textiles and plastic films to printing and lamination—one component is absolutely critical to the quality of your final product: the Industrial Roller used for heating. If this roller fails to provide consistent, uniform heat or, worse, damages the delicate material surface, your entire production line can grind to a halt, leading to wasted material and massive losses.

For any industrial buyer searching for a permanent solution to poor heat transfer, surface defects, and high maintenance costs, the answer lies in precision-engineered rollers.

This is where Siva Rollers, the best Heat Transfer Roller manufacturer & supplier in India, provides the expertise and technology to ensure your operation runs smoothly, profitably, and with unmatched product quality.

The Hidden Costs of Inconsistent Heating: Problems Industrial Buyers Face

If you are a Plant Manager, Procurement Head, or Production Engineer, you know the daily struggle. Your equipment is only as good as its weakest link, and often, that link is the Heating Roller. Many Indian industrial buyers face these critical, expensive issues when working with sub-par rollers:

The Scrap Material Nightmare

The primary job of a heat transfer roller is to apply a precise amount of heat across the entire width of the material (web).

- Problem: If the temperature is uneven—hot in the center, cool on the edges, or fluctuating over time—the material will be inconsistently processed. This leads to defects like bubbling in lamination, uneven curing in coatings, or patchy prints in textile sublimation. The result? High scrap rates, which directly impact your bottom line.

- Buyer Intent Solution: You need a Precision Roller designed for perfect thermal uniformity, minimizing costly material waste.

Excessive Downtime and Maintenance

In many older or lower-quality systems, Thermal Oil Roller designs can suffer from internal issues. Over time, the heat transfer oil can break down (carbonize), creating deposits on the inner shell.

- Problem: These deposits act as insulation, severely reducing heat transfer efficiency. The machine operator must then raise the oil temperature just to hit the target surface temperature, stressing the system further. Eventually, the roller has to be removed for costly internal cleaning, causing unexpected production stoppages (downtime).

- Buyer Intent Solution: You need a roller built with advanced internal flow dynamics (like a Double Shell Roller) that resists fouling and is guaranteed for longevity, ensuring maximum uptime.

Surface Damage and Defects

The roller’s surface finish is crucial, especially when working with high-value materials like films, high-gloss paper, or delicate fabrics.

- Problem: If the roller is not manufactured with micron-level precision and a superior surface finish (e.g., mirror chrome or hard-coated), it can scratch, crease, or leave marks on the material. Furthermore, uneven pressure or localized hotspots can warp the material.

- Buyer Intent Solution: You need a supplier who is an expert Industrial Roller Manufacturer in India with capabilities in precision grinding and finishing, ensuring the “zero surface damage” promise.

The Siva Rollers Solution: Precision, Consistency, and Control

Siva Rollers understands that a roller is not just a piece of metal; it is the heart of your thermal process. As the best Heat Transfer Roller manufacturer & supplier in India, our philosophy revolves around combining robust mechanical strength with unparalleled thermal performance.

We classify our offerings not just by material, but by the critical function they perform: achieving perfect Temperature Control Roll results.

Double Shell Roller Technology: The Secret to Uniform Heating

For high-speed, high-precision thermal applications, the traditional single-shell roller design is simply outdated. It struggles with temperature fluctuations, especially at the edges of the web.

Siva Rollers specializes in the advanced Double Shell Roller design.

- How it Works: The Double Shell Roller consists of an outer working shell and an inner shell. The thermal fluid (like oil or water) is channeled at a high velocity through the narrow annulus (space) between the two shells, often guided by a spiral baffle.

- The Benefit: This forced, turbulent flow drastically improves the heat transfer coefficient, ensuring that the fluid quickly and efficiently transfers its heat to the outer surface shell. This results in far greater end-to-end temperature uniformity (minimal variation from the center to the edge) compared to conventional designs.

Choosing the Right Heating System for Your Needs

The ideal Heating Roller system depends entirely on your temperature range, lines speed, and cleanliness requirements. Siva Rollers manufactures rollers for all major thermal types:

Roller Type | Ideal Temperature Range | Key Advantage for Buyers | Typical Applications |

Thermal Oil Roller | Up to 350°C | Cost-effective for high thermal loads and large rollers. | Lamination, calendar rolls, continuous coating lines. |

Electric Heating Roller | Up to 400°C+ | Ultra-precise temperature control, fast heating/cooling, no fluid leaks. | Printing, heat-setting, specialized plastic extrusion (where cleanliness is paramount). |

Chill & Heat Transfer Roller | Cooling to Heating | Maximum versatility; can cool the material after heating or quickly change between thermal states. | Printing presses, coating lines where immediate cooling post-treatment is necessary. |

For small-scale or highly flexible operations, we also supply solutions for the mini heat transfer roller machine segment, ensuring even emerging businesses have access to Siva Rollers’ quality.

Applications and Equipment: Where Our Precision Rollers Shine

The need for a reliable Precision Roller extends across dozens of industries. Siva Rollers provides the critical component that powers your major machinery:

The Heat Transfer Roller Press

In sublimation printing, textile manufacturing, and certain laminating processes, a heat transfer roller press or a heat transfer roller machine is necessary to apply heat and pressure simultaneously. The quality of the final transfer—be it a vibrant dye on fabric or a durable protective film—depends entirely on the uniformity of the roller.

Our rollers are engineered for:

- Perfect Pressure Tolerance: Built to withstand the high pressures of a press without deforming.

- Zero Roll Deflection: Ensuring the roller maintains a straight, cylindrical shape even under extreme load, preventing uneven pressure and heat spots.

B. Industrial Manufacturing Processes

Every Industrial Roller we create is tailored for maximum performance in its specific environment:

- Textiles: Ensuring uniform heat-setting and dye sublimation, eliminating colour variations.

- Lamination & Coating: Providing the exact temperature necessary to cure adhesives or polymer coatings, guaranteeing perfect bonding without bubbles or delamination.

- Plastic Film & Sheet Production: Used as Chill & Heat Transfer Roller to manage the plastic’s temperature profile as it’s extruded and formed, ensuring consistency in thickness and finish.

Siva Rollers: Your Trusted Industrial Roller Manufacturer in India

Choosing the right supplier is about more than just finding the lowest price; it’s about securing reliability, quality, and technical partnership.

Unmatched Manufacturing Precision

At Siva Rollers, we pride ourselves on being a world-class Industrial Roller Manufacturer in India. Our processes are built around delivering a Precision Roller every time:

- Material Selection: We use only the highest-grade materials (carbon steel, stainless steel, alloys) chosen for optimal thermal conductivity and mechanical strength, tailored for your specific Temperature Control Roll requirements.

- Advanced Internal Engineering: Our designs use Computational Fluid Dynamics (CFD) modeling to perfect the flow path within the Double Shell Roller, maximizing turbulence while minimizing pressure drop. This ensures the best possible heat transfer performance and prevents internal fouling.

- Mirror Finish & Hard Coatings: We offer specialised finishes like hard chrome plating and superior polymer coatings to ensure the absolute minimum coefficient of friction, guaranteeing zero surface damage to your web material.

Built for Indian Conditions

We understand the unique demands of the Indian industrial landscape—high output, challenging environmental conditions, and the need for cost-effective reliability.

- Our Thermal Oil Roller systems are designed with high-quality seals and robust engineering to minimize the risk of oil leaks, improving both safety and cleanliness on the shop floor.

- Our Electric Heating Roller systems offer a clean, piping-free installation, reducing maintenance complexity, a significant advantage in environments where fluid systems are challenging to manage.

Commitment to Energy Efficiency

Efficiency is profit. Our Heating Roller designs—especially the Double Shell Roller configuration—are inherently more energy-efficient because they achieve the target surface temperature faster and maintain it with less thermal fluid input. This directly translates to lower energy bills and reduced operational costs for your heat transfer roller machine.

Addressing Your Core Pain Points Directly

If your current rollers are causing headache and loss, here is how Siva Rollers solves your pain:

Your Problem | The Siva Rollers Solution | Key Benefit to Your Business |

Uneven Temperatures | Double Shell Roller design with spiral baffling for uniform fluid flow. | Eliminates scrap due to uneven curing or printing; ensures 100% product quality. |

High Maintenance/Downtime | Robust construction and superior internal flow dynamics that resist carbonization. | Maximises uptime and significantly extends the service life of your Thermal Oil Roller. |

Surface Scratching/Marks | Precision Roller manufacturing, mirror-polished surfaces, and optional specialty coatings. | Protects valuable materials, guaranteeing a pristine, defect-free final product. |

Need for Ultra-High Speed | High-wattage Electric Heating Roller options that transfer heat faster than oil systems. | Increased production speed and higher throughput without compromising temperature stability. |

Partnering with Siva Rollers for Consistent Success

The efficiency, quality, and consistency of your industrial output hinge on the performance of your Temperature Control Roll. Settling for a generic roller means accepting inconsistent heating, higher scrap rates, and the risk of catastrophic surface damage.

If you are an industrial buyer in India looking for a genuine competitive edge, it is time to upgrade your system with a roller that is engineered for perfection.

Siva Rollers is not just a supplier; we are your partner in production excellence, offering the most reliable Precision Roller and Double Shell Roller solutions on the market. From the smallest mini heat transfer roller machine to the largest heat transfer roller press, our commitment to quality as the leading Industrial Roller Manufacturer in India remains absolute.

Ready to eliminate scrap and achieve perfectly consistent product quality?

Contact the experts at Siva Rollers today to discuss your specific thermal requirements. Let us custom-design the perfect Heat Transfer Roller to power your success.

FAQs

The primary difference lies in thermal control and consistency. A single-shell roller has one fluid path, which often leads to inconsistent temperature profiles (hotter in the center, cooler at the edges). The Double Shell Roller uses a secondary inner shell to create a narrow, high-velocity channel (annulus) for the thermal fluid. This forces turbulent flow, which dramatically increases the heat transfer rate and ensures highly uniform Temperature Control Roll performance across the entire web width. This is critical for high-precision applications.

Electric Heating Rollers offer two main advantages:

- Higher Temperatures and Precision: They can typically achieve higher temperatures (up to 400°C+) and offer faster, more precise temperature ramping and control.

- Cleanliness and Maintenance: They eliminate the need for thermal oil systems, meaning zero risk of oil leaks, fluid decomposition (carbonization), or piping maintenance, making them ideal for sterile or complex machinery where cleanliness is paramount.

To ensure zero surface damage, Siva Rollers utilizes advanced finishing techniques:

- Mirror Chrome Finish: Achieves extremely low surface roughness (Ra values often below 0.5), providing a flawless, non-stick surface perfect for films and delicate materials.

- Specialty Coatings: We offer hard coatings (like tungsten carbide) and advanced polymer coatings (like Teflon/PTFE) for superior durability, non-stick properties, and corrosion resistance under extreme operating conditions.

Yes, Siva Rollers provides precision solutions across the full size spectrum. Whether you operate a large-scale heat transfer roller press or a compact mini heat transfer roller machine, we apply the same high standards of engineering and material quality, ensuring you get a reliable, custom-designed Heat Transfer Roller suited to your exact specifications.

A poor-quality Thermal Oil Roller often uses substandard internal design that allows thermal oil to break down and form insulating deposits. This forces you to run the system hotter and less efficiently, eventually requiring the expensive, unscheduled removal of the roller for cleaning. By investing in a high-quality, efficient Industrial Roller Manufacturer in India like Siva Rollers, you minimize internal fouling and significantly extend the time between maintenance, leading to maximized uptime and lower long-term operational costs.

As a leading Industrial Roller Manufacturer in India, Siva Rollers uses materials selected specifically for thermal performance and structural integrity. Common materials include high-grade Carbon Steel (for strength and thermal conductivity) and Stainless Steel (for corrosion resistance, crucial in food, pharmaceutical, or chemical processing). The right material ensures the roller can withstand high operational temperatures and pressures while maintaining the correct mechanical properties needed for a high-performance Precision Roller.

In laminar (smooth) flow, the thermal fluid right next to the shell surface moves slowly, creating an insulating layer that hinders heat transfer. The turbulent flow, forced by the internal spiral baffle in a Double Shell Roller, constantly disrupts this boundary layer. This high-speed mixing allows the hot fluid to touch the outer shell directly and continuously, drastically increasing the heat transfer coefficient and ensuring the roller quickly achieves and consistently maintains the required Temperature Control Roll setting.

The Chill & Heat Transfer Roller is designed for versatility, capable of circulating both heating fluid (e.g., hot oil) and cooling fluid (e.g., chilled water) through the same internal channels. This allows manufacturers to quickly ramp temperatures up or down. It is commonly used in coating and lamination lines where the material must be heated for curing/bonding and then immediately cooled to set the structure or adhesive.

Siva Rollers specializes in micro-tolerance manufacturing. Our Precision Roller products guarantee extremely low Total Indicator Runout (TIR)—often measured in microns (µm)—to ensure perfect rotational accuracy. This precision is vital for high-speed applications like the heat transfer roller machine to eliminate vibration and ensure uniform nip pressure, which directly prevents material flaws and guarantees the roller performs as a true Temperature Control Roll.

Absolutely. Customization is a core strength of Siva Rollers, your trusted Industrial Roller Manufacturer in India. We routinely customize:

- Dimensions: Length, diameter, and shaft configurations.

- Internal Design: Optimization of the Double Shell Roller baffle pitch based on fluid viscosity and flow rate.

- Surface Finish: Specific coatings (e.g., hard chrome, ceramic, or Teflon) tailored to the material being processed to ensure zero surface damage and optimal release properties. We engineer the Heat Transfer Roller to fit your exact production need