Trusted Industrial Rollers Supplier for Paper, Printing & Packaging Industries

In the world of high-speed manufacturing, the smallest component often carries the heaviest responsibility. Whether you are running a massive paper mill, a high-precision offset printing press, or a sophisticated flexible packaging line, your productivity depends on one critical element: Industrial Rollers.

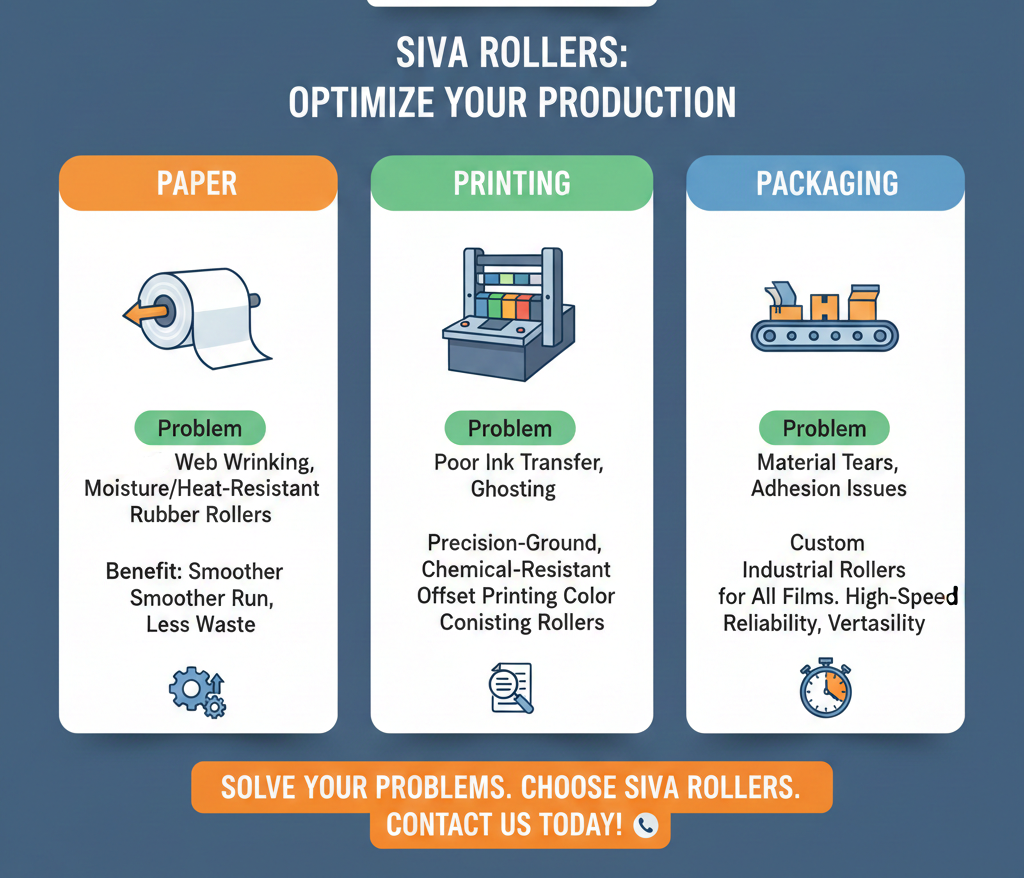

Choosing the right Industrial Rollers Manufacturer is not just about buying a part; it is about securing the efficiency of your entire production floor. At Siva Rollers, recognised as the Best Industrial Rollers Manufacturer & Supplier in India, we understand that downtime is your biggest enemy. This guide explores how high-quality rollers solve common industrial problems and why your choice of supplier determines your market competitiveness.

The Critical Role of Industrial Rollers in Modern Manufacturing

Industrial rollers are the heart of web-fed processing. They facilitate the movement, treatment, and finishing of materials ranging from delicate tissue paper to heavy-duty metal foils. However, not all rollers are created equal.

As a leading Industrial Rollers Supplier, we see first hand how substandard rollers lead to:

- Material wastage due to improper tension.

- Inconsistent ink transfer in printing.

- Frequent machine breakdowns.

- Increased energy consumption.

By partnering with an expert Industrial Rollers Manufacturer in India, businesses can transition from reactive maintenance to proactive growth.

1. Precision Solutions for the Printing Industry

The printing industry demands extreme accuracy. Whether you are dealing with newspapers, magazines, or specialised labels, the rollers must provide consistent pressure and chemical resistance.

Offset Printing Rollers

For those in the commercial printing space, Offset printing rollers are vital. These rollers must manage the delicate balance between ink and water. At Siva Rollers, we engineer these to resist swelling and shrinking, ensuring that your dot gain remains minimal and your print quality remains sharp from the first copy to the last.

Printing Roller Manufacturer Expertise

As a specialized Printing Roller Manufacturer, we focus on surface finish. A roller with the wrong roughness (RA value) can cause “ghosting” or uneven solids. Our rollers are calibrated to meet the exact specifications of brands like Heidelberg, Komori, and Mitsubishi, making us the preferred choice for high-end print houses.

2. Robust Performance for the Paper Industry

Paper mills operate under some of the harshest conditions—high heat, constant moisture, and immense pressure.

Why Material Choice Matters

In paper production, rollers are used for everything from dewatering to calendering. Using a generic roller leads to surface degradation. As a premier Rubber Roller Manufacturer, we utilise advanced polymers that withstand the heat generated during high-speed paper winding. Our Custom industrial rollers are designed with specific shore hardness to ensure the paper web is handled gently yet firmly, preventing tears and reducing scrap rates.

3. High-Speed Reliability for the Packaging Sector

The packaging industry is currently seeing a massive shift toward sustainable and flexible materials. This requires rollers that can handle a variety of substrates, including BOPP, PET, and recycled paper.

Custom Industrial Rollers for Packaging

Packaging lines often require unique dimensions and coatings. Whether it is a silicone-coated roller for adhesive applications or a hard-chromed roller for lamination, Siva Rollers provides tailor-made solutions. Our role as a Custom industrial rollers specialist allows us to modify core designs and surface treatments to match your specific machinery requirements.

Why Choose Siva Rollers: Best Industrial Rollers Manufacturer & Supplier in India

When you search for an Industrial Rollers Manufacturer in India, you will find many options. However, Siva Rollers stands out because we combine traditional craftsmanship with modern engineering.

Engineering Excellence

We don’t just “make” rollers; we engineer them. Our process includes:

- Core Inspection: Ensuring the metal shaft is perfectly balanced to prevent vibration at high speeds.

- Material Science: Selecting the right rubber or polyurethane compound based on your industry’s chemical exposure.

- Precision Grinding: Achieving micron-level tolerances for perfectly cylindrical or crowned profiles.

Local Expertise, Global Standards

Being a prominent Industrial Rollers Supplier, we serve clients across the globe from our base in India. We understand the local operational challenges—voltage fluctuations affecting motor speeds and ambient temperature changes—and we build our rollers to be resilient under these conditions.

Common Industrial Problems Solved by Quality Rollers

Many plant managers face recurring issues that they blame on the machine, when the culprit is actually the roller.

Problem: Web Wrinkling

Solution: Using spreader rollers or precisely crowned rollers from a trusted Industrial Rollers Manufacturer. We analyse your web path to recommend the exact degree of crowning needed to keep your material flat and smooth.

Problem: Ink Stripping or Piling

Solution: This usually happens when the rubber compound reacts poorly with modern inks. As a dedicated Rubber Roller Manufacturer, we offer specialized compounds that are “ink-friendly,” ensuring smooth transfer and easy cleaning.

Problem: Short Roller Life

Solution: High-quality vulcanization. Many local suppliers rush the curing process. At Siva Rollers, we follow strict temperature-time cycles to ensure the rubber-to-metal bond is unbreakable, significantly extending the life of your equipment.

The Economics of Quality: Transactional Value

Investing in premium rollers from a top Industrial Rollers Manufacturer in India is a financial decision as much as a technical one.

- Reduced Downtime: If your line stops for two hours to change a failed roller, the loss in production often exceeds the cost of a new, high-quality roller.

- Lower Maintenance Costs: Better rollers put less strain on bearings and motors.

- Increased Yield: High-precision Offset printing rollers and packaging rollers reduce the amount of “bad” product you have to throw away.

How to Select the Right Industrial Rollers Supplier

Before placing an order, consider these three factors:

- Technical Support: Does the supplier understand your specific application? A good Industrial Rollers Manufacturer asks about your chemicals, speeds, and temperatures.

- Customization Capability: Can they manufacture Custom industrial rollers, or do they only sell “off-the-shelf” sizes?

- Track Record: Look for a brand like Siva Rollers—the Best Industrial Rollers Manufacturer & Supplier in India—with a proven history of serving the Paper, Printing, and Packaging giants.

Partner with Siva Rollers Today

In the competitive landscape of the Paper, Printing, and Packaging industries, your machinery is only as good as the rollers that drive it. Don’t let a “cheap” roller become an expensive mistake.

Siva Rollers is committed to solving your production hurdles through innovation and quality. Whether you need a single Rubber Roller Manufacturer to refurbish your old stock or a complete set of Printing Roller Manufacturer solutions for a new installation, we are here to help.

Contact Siva Rollers today—your trusted Industrial Rollers Manufacturer in India—to optimize your production line for maximum efficiency.

CONTACT US

FAQs

Industrial rollers are precision-engineered components used to move, coat, press, laminate, or guide materials in continuous production lines. In paper, printing, and packaging industries, they directly control material tension, surface finish, ink transfer, and production speed. Poor-quality rollers cause wastage, downtime, and inconsistent output.

Choose an industrial rollers manufacturer in India that offers application-specific engineering, custom roller design, proven material expertise, and post-sales technical support. A reliable manufacturer like Siva Rollers evaluates your machine speed, chemicals, temperature, and load conditions before recommending the roller solution.

Printing machines demand extreme accuracy because even minor surface variation can cause ghosting, ink piling, or uneven print density. Precision printing rollers ensure correct ink-water balance, stable pressure, and consistent dot gain, especially in offset printing and high-speed presses.

Offset printing rollers are engineered to resist ink, fountain solution chemicals, and heat without swelling or shrinking. Unlike generic rubber rollers, offset rollers from an experienced printing roller manufacturer maintain surface integrity and print consistency throughout long production runs.

Paper mills operate in high heat, moisture, and pressure environments. Incorrect roller material leads to cracking, glazing, or rapid wear. As a specialized rubber roller manufacturer, Siva Rollers uses advanced rubber and polyurethane compounds with controlled shore hardness to protect paper quality and reduce breakage.

Low-quality industrial rollers often result in web wrinkling, ink stripping, short roller life, frequent machine stoppages, and higher energy consumption. These issues are frequently misdiagnosed as machine faults when the real cause is improper roller design or compound selection.

Custom industrial rollers are designed to match exact machine dimensions, substrate types, and surface requirements. In packaging applications—such as BOPP, PET, or lamination—custom rollers improve grip, alignment, adhesive control, and speed stability, leading to higher output and lower rejection rates.

Packaging rollers commonly use silicone coatings for adhesive applications, PU coatings for abrasion resistance, and hard chrome for lamination and slitting processes. A knowledgeable industrial rollers supplier recommends coatings based on substrate behavior, temperature, and chemical exposure.

High-quality rubber rollers use proper vulcanization cycles, strong rubber-to-metal bonding, and precision grinding. This prevents premature delamination, surface cracking, and imbalance—significantly extending roller life and reducing replacement frequency.

Yes. Precision-engineered industrial rollers reduce vibration, bearing stress, and uneven load distribution. This leads to fewer breakdowns, smoother machine operation, and lower maintenance costs, making premium rollers a cost-saving investment rather than an expense.

Siva Rollers combines material science, precision engineering, and industry-specific customization. With expertise across paper, printing, and packaging sectors, the company delivers globally compliant rollers engineered for Indian operating conditions, ensuring durability, accuracy, and consistent performance.

Industrial rollers should be replaced or reconditioned when surface wear, hardness change, vibration, or print defects appear. Delaying replacement increases scrap rates and machine stress. A professional rubber roller manufacturer can assess whether refurbishment or new rollers offer better long-term value.