What Are Stainless Steel Rollers? Uses & Benefits for Industries

In modern manufacturing, printing, packaging, textile, and converting industries, efficiency and precision depend heavily on the quality of rollers used in production lines. Among the many types of industrial rollers available, deflection rollers—also known as anti-deflection rollers—play a critical role in ensuring uniform web tension, reducing sagging, and maintaining high-quality output, especially in applications where wide web materials and heavy loads are involved.

This guide provides a complete understanding of deflection rollers, their design, applications, benefits, and why every industrial buyer should prioritize them when upgrading or installing production equipment.

Understanding Deflection Rollers

Deflection rollers are specialized industrial rollers designed to counteract bending or sagging that typically occurs when processing wide webs or heavy materials on a production line. Standard rollers tend to bend or “deflect” under load, especially when the width of the web (material) is large. This deflection leads to uneven tension, misalignment, and product inconsistencies.

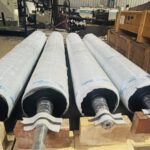

Deflection rollers, or anti-deflection rollers, are engineered with a unique internal structure that minimizes this bending effect. They are often built with high-strength materials like steel, aluminum, or carbon fiber and feature internal supports such as fixed shafts, special bearings, and dynamically balanced bodies to maintain straightness under heavy load.

By controlling deflection, these rollers help industries achieve consistent tension, better alignment, and improved product quality, making them an essential component for demanding production processes.

Why Do Industries Need Deflection Rollers?

In any continuous web handling process—such as film, foil, textile, or paper processing—roller deflection is a major challenge. When a roller bends, even slightly, it can cause:

- Uneven web tension, leading to wrinkles or stretching.

- Poor product alignment, causing defects during printing or coating.

- Increased wear on machinery due to misalignment.

- Lower production efficiency and higher maintenance costs.

Deflection rollers solve these problems by maintaining uniformity, even with wide webs and heavy weights, helping companies increase throughput, reduce downtime, and enhance end-product quality.

Key Features of Deflection Rollers

Deflection rollers differ from conventional rollers because of their precision engineering and load-bearing capabilities. Some of the defining features include:

- Anti-deflection design: The core structure and bearings are specifically designed to resist bending under load.

- Lightweight yet strong materials: Materials like high-grade aluminum or steel alloys are often used to balance strength and weight.

- Dynamic balancing: Ensures vibration-free operation at high speeds, improving process stability.

- High load capacity: Suitable for handling wide webs, films, foils, and heavy substrates.

- Smooth rotation and minimal friction: Reduces wear and energy consumption during operation.

These features make them an integral part of printing presses, laminators, packaging lines, and textile machinery.

Applications of Deflection Rollers in Industry

Deflection rollers are used across a wide range of industries where precision and high-quality output are essential. Some of the most common applications include:

- Printing and Packaging: For gravure, flexographic, and offset printing machines, deflection rollers maintain even tension across wide webs to ensure high-quality prints without distortion.

- Paper and Pulp: Used in converting lines, coating, and laminating systems where wide paper webs are processed.

- Plastic Film and Foil Processing: Essential for extrusion, lamination, and slitting processes, where material stretching or wrinkling must be avoided.

- Textile Industry: Helps in fabric coating, printing, and finishing by ensuring straight, wrinkle-free material movement.

- Steel and Metal Coil Handling: For heavy-duty applications, anti-deflection rollers withstand the load of metal strips and coils without bending.

By offering versatility and reliability, deflection rollers contribute significantly to industrial efficiency and output quality.

Benefits of Using Deflection Rollers

For industrial buyers, investing in deflection rollers can deliver long-term advantages, including:

- Consistent Web Tension: Eliminates wrinkles, stretching, or misalignment even in wide web applications.

- Improved Product Quality: Supports accurate printing, laminating, and coating by ensuring smooth, controlled material movement.

- Extended Equipment Life: Reduces mechanical strain and wear on other machine parts.

- Higher Production Speeds: Balanced and vibration-free operation allows machines to run at higher speeds without compromising output.

- Reduced Maintenance Costs: Built for durability, deflection rollers require minimal maintenance compared to standard rollers.

- Energy Efficiency: Smooth, low-friction operation lowers energy consumption in production lines.

These benefits translate to higher ROI (Return on Investment) for businesses in competitive markets.

Choosing the Right Deflection Roller

Selecting the right deflection roller depends on factors such as:

- Material Type: The kind of web (film, foil, paper, textile, or metal) you are processing.

- Web Width and Load: Wider, heavier webs require rollers with greater anti-deflection capability.

- Operating Speed: High-speed operations need dynamically balanced rollers for stable performance.

- Surface Coating: Options like chrome, rubber, or plasma coating can be added for better grip, wear resistance, and longer life.

- Industry-Specific Requirements: Printing and packaging lines may require different roller specifications than textile or metal processing plants.

Partnering with a trusted roller manufacturer ensures that you get customized solutions for your production needs.

Why Work with a Professional Roller Manufacturer?

When it comes to industrial rollers, especially anti-deflection rollers, quality manufacturing is critical. Working with an experienced roller manufacturer offers benefits such as:

- Custom Engineering: Tailored roller designs for your machinery and process requirements.

- High-Quality Materials: Assurance of durability and performance under demanding conditions.

- Precision Balancing and Finishing: Ensures smooth operation and reduced machine downtime.

- Technical Support: Expert advice on selecting, installing, and maintaining rollers for peak efficiency.

This is where Siva Rollers stands out as the best deflection rollers manufacturer in India. With years of expertise in producing industrial rollers, including anti-deflection rollers, Siva Rollers provides customized, precision-engineered solutions for printing, packaging, paper, and textile industries. Their commitment to quality, durability, and customer support makes them a preferred partner for leading manufacturers and processors across India and abroad.

Future Trends in Deflection Rollers

As industries evolve, deflection roller technology is also advancing. Some emerging trends include:

- Use of Lightweight Composite Materials: Carbon fiber and advanced alloys for reduced weight and enhanced strength.

- Enhanced Coatings: Wear-resistant and anti-static coatings for better performance and durability.

- Smart Rollers: Integration of sensors to monitor tension, temperature, and alignment in real time.

- Eco-Friendly Manufacturing: Focus on energy-efficient production and recyclable materials to support sustainable practices.

Industrial buyers investing in the latest deflection roller technology can future-proof their production lines and maintain a competitive edge.

Final Thoughts

Deflection rollers are a vital component for industries that handle wide webs, heavy loads, and high-speed production. Their ability to eliminate deflection, maintain consistent web tension, and enhance product quality makes them indispensable for printing, packaging, textile, paper, and film processing sectors.

For industrial buyers, choosing the right roller manufacturer is just as important as selecting the right roller. With Siva Rollers, you can rely on premium-quality deflection rollers, engineered to meet the toughest operational challenges. Whether you need standard or anti-deflection rollers, Siva Rollers delivers performance, precision, and reliability—helping your production lines achieve maximum efficiency.

FAQs

Deflection rollers, also known as anti-deflection rollers, are industrial rollers designed to resist bending when processing wide or heavy materials. They use a strong core, internal supports, and dynamic balancing to maintain straightness and even web tension.

Anti-deflection rollers prevent sagging and uneven tension, ensuring smooth, wrinkle-free material movement. This leads to sharper printing, better coating, and improved product quality.

Industries such as printing, packaging, food and beverage, textiles, pharmaceuticals, and metal processing frequently use stainless steel rollers due to their reliability.

By reducing wrinkles, stretching, and machine strain, deflection rollers allow faster line speeds, minimize downtime, and improve final product consistency.

Most deflection rollers are built with high-grade steel, aluminum, or composites like carbon fiber for strength, durability, and lightweight handling.

Factors like web width, material weight, operating speed, and required surface coatings (such as chrome or rubber) should guide your choice. Working with a professional roller manufacturer ensures a perfect match.

Yes. Heavy-duty anti-deflection rollers are engineered to carry the load of metal coils and strips without bending, ensuring smooth handling.

Yes. Experienced roller manufacturers like Siva Rollers offer fully customized deflection rollers to meet industry-specific needs, dimensions, and material requirements.

With proper maintenance and high-quality manufacturing, deflection rollers can last several years, even under continuous heavy-duty use.

Siva Rollers is one of the leading deflection roller manufacturers in India, offering precision-engineered, durable rollers for printing, packaging, paper, and textile industries.