What Are Stainless Steel Rollers? Uses & Benefits for Industries

In today’s fast-paced industrial world, businesses rely heavily on precision-engineered components that deliver durability, performance, and efficiency. One such essential component is the stainless steel roller. Found in industries ranging from printing and packaging to food processing and steel manufacturing, these rollers are crucial for smooth operations and consistent output. But what exactly are stainless steel rollers, why are they used across so many sectors, and how do they benefit industrial processes?

This detailed guide explores what stainless steel rollers are, their industrial uses, their key benefits, and why choosing a trusted stainless steel rollers manufacturer like Siva Rollers can make a difference for your business.

What Are Stainless Steel Rollers?

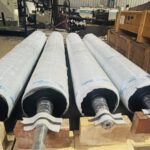

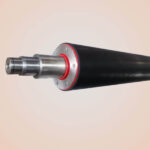

Stainless steel rollers are precision-engineered cylindrical components made from high-grade stainless steel, designed to transport, guide, or press materials in industrial applications. Unlike regular steel rollers, stainless steel variants offer superior resistance to corrosion, wear, and chemical exposure, making them ideal for industries that demand long-lasting performance and hygienic handling.

These rollers are crafted using different stainless steel grades, including 304, 316, and 410, depending on the specific application. Their construction ensures excellent load-bearing capacity, dimensional stability, and the ability to withstand extreme environments such as high humidity, corrosive chemicals, or abrasive materials.

Stainless steel rollers can be plain, grooved, knurled, or coated depending on the operation they are designed for. They are widely used in conveyors, food-grade processing lines, laminators, packaging machines, and printing presses.

Why Are Stainless Steel Rollers Essential for Industries?

Every industry relies on efficiency and reliability. Components like rollers must endure rigorous conditions—heat, pressure, chemicals, and continuous operation—without breaking down. Stainless steel rollers are preferred because they are incredibly durable and versatile.

Their smooth surface prevents product contamination, which is particularly crucial for food, beverage, and pharmaceutical applications. In contrast to mild steel or coated rollers, stainless steel rollers last longer, require less maintenance, and reduce overall operational costs.

For companies looking for consistent quality and reliability, partnering with a trusted roller manufacturer ensures the right grade, design, and finish are selected based on the industrial need.

Key Industrial Applications of Stainless Steel Rollers

Stainless steel rollers are versatile and used across multiple industries, including:

Printing and Packaging:

In printing and packaging, rollers ensure precise material feeding, lamination, and coating. Their smooth surface prevents scratching or contamination, making them ideal for high-speed production lines.

Food and Beverage Industry:

Stainless steel’s non-reactive and corrosion-resistant properties make it the top choice for hygienic applications. These rollers are commonly found in bakery conveyors, meat processing equipment, and beverage bottling plants, ensuring compliance with food safety standards.

Textile Industry:

In textile manufacturing, stainless steel rollers help in guiding, stretching, and finishing fabrics. Their durability and smooth finish ensure fabric quality without causing snags or damage.

Steel, Paper, and Plastic Processing:

From guiding sheets in steel plants to laminating paper or plastic, these rollers withstand heavy loads and harsh conditions, ensuring a seamless production process.

Pharmaceuticals and Chemicals:

Stainless steel rollers are vital in chemical and pharma industries due to their ability to resist corrosion and maintain hygienic standards, even when exposed to aggressive substances.

Benefits of Stainless Steel Rollers for Industries

Durability and Longevity:

Stainless steel rollers have a significantly longer lifespan compared to conventional rollers. They resist wear and tear, reducing the frequency of replacements and downtime.

Corrosion and Chemical Resistance:

One of the standout features of stainless steel is its ability to resist corrosion from water, chemicals, and other industrial substances. This makes these rollers ideal for industries with exposure to moisture and chemicals.

Hygienic and Easy to Clean:

For food, beverage, and pharmaceutical industries, hygiene is non-negotiable. Stainless steel’s smooth surface is easy to sanitize, ensuring compliance with stringent hygiene standards.

Low Maintenance Costs:

Due to their robust nature, stainless steel rollers require minimal maintenance, lowering operational costs over time.

Versatility in Applications:

From high-temperature environments to moisture-prone settings, stainless steel rollers perform well across diverse applications.

Smooth and Reliable Operation:

These rollers ensure consistent material handling, reducing the chances of jams, scratches, or product damage during processing.

Why Choosing the Right Stainless Steel Rollers Manufacturer Matters

Not all rollers are created equal, and the quality of a roller can directly impact production efficiency and product quality. Choosing the right stainless steel rollers manufacturer ensures that the rollers are built to exact specifications, using the right grade of steel, and tested for performance.

A trusted manufacturer will also offer customized solutions based on the industry, whether it’s a food-grade roller for a bakery line or a heavy-duty roller for a steel processing plant.

Siva Rollers – The Best Stainless Steel Rollers Manufacturer in India

When it comes to sourcing high-quality stainless steel rollers, Siva Rollers stands out as a trusted name in India. With years of expertise as a leading industrial roller manufacturer, Siva Rollers delivers precision-engineered solutions for industries like printing, packaging, textiles, steel, food, and pharmaceuticals.

Siva Rollers is known for:

- Using premium stainless steel grades like 304, 316, and 410 for various industrial applications.

- Offering customized roller designs tailored to specific machinery and production needs.

- Ensuring strict quality control for durability, corrosion resistance, and dimensional accuracy.

For businesses looking to buy reliable stainless steel rollers in India, Siva Rollers is a go-to partner that combines quality, affordability, and fast delivery.

How to Choose the Right Stainless Steel Roller for Your Industry?

Selecting the right roller depends on the operational environment and the type of materials being processed. Factors to consider include:

- The grade of stainless steel (304, 316, or 410) for the specific application.

- The type of roller finish—plain, coated, or grooved.

- Load-bearing requirements and operating temperatures.

- Whether the roller needs to meet hygienic or chemical-resistant standards.

Consulting with an experienced roller manufacturer like Siva Rollers ensures that your selection matches your production requirements perfectly.

Investing in Stainless Steel Rollers for Long-Term Gain

Stainless steel rollers are an indispensable part of modern industrial operations, offering unmatched durability, corrosion resistance, and versatility. From ensuring hygienic processing in the food industry to handling heavy-duty operations in steel plants, these rollers improve efficiency and reduce downtime.

For companies in India looking for top-quality rollers, Siva Rollers provides cutting-edge solutions as a leading stainless steel rollers manufacturer. By choosing the right rollers for your industry, you can significantly enhance performance, lower maintenance costs, and ensure smooth, reliable production.

FAQs

Stainless steel rollers are used for transporting, guiding, pressing, or laminating materials in industries like printing, food processing, packaging, textiles, and steel manufacturing.

Stainless steel rollers offer higher corrosion resistance, durability, and hygienic properties, making them ideal for demanding industrial and food-grade environments.

Industries such as printing, packaging, food and beverage, textiles, pharmaceuticals, and metal processing frequently use stainless steel rollers due to their reliability.

Common stainless steel grades include 304, 316, and 410, selected based on application needs like chemical resistance, strength, or hygiene standards.

Yes, stainless steel rollers can be customized in terms of size, surface finish, load capacity, and coating to suit specific industrial machinery and applications.

They ensure sanitary material handling, resist rust and bacterial growth, and comply with food safety regulations—ideal for bakeries, bottling, and meat plants.

With proper maintenance, stainless steel rollers can last several years, thanks to their high resistance to wear, corrosion, and mechanical stress.

Siva Rollers is widely recognized as one of the best stainless steel roller manufacturers in India, known for quality, customization, and industry expertise.

Yes, stainless steel rollers can withstand high temperatures, making them suitable for industrial environments involving heat, steam, or thermal processes.

Choosing the right roller depends on load, speed, material type, environment, and whether you need hygienic or chemical-resistant performance. A manufacturer like Siva Rollers can guide you.