What Is a Printing Roller? A Quick Guide for Industrial Use

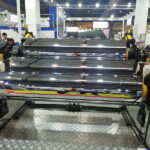

In the industrial printing world, the printing roller is the heart of any machinery that demands precision, consistency, and durability. Whether it’s flexographic, gravure, or offset printing—rollers play a pivotal role in transferring ink to various substrates efficiently and evenly. Understanding what a printing roller is, how it works, and why it matters is essential for plant managers, maintenance engineers, and procurement teams in high-output industries.

Understanding the Printing Roller

A printing roller is a cylindrical component used to apply ink, coatings, or pressure during printing processes. It is a critical part of industrial printing machines used in packaging, textiles, plastic films, paper production, and more. The roller’s surface, hardness, and coating material determine its performance, lifespan, and compatibility with inks and substrates.

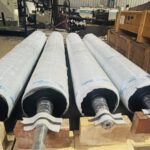

Printing rollers are typically constructed with a metallic core—often steel or aluminum—and coated with rubber or synthetic polymers for specific printing applications. The type and quality of the coating define the roller’s suitability for different industrial printing tasks.

The Role of the Printing Rubber Roller

The printing rubber roller is a specialized roller that uses a rubber-coated surface to ensure uniform ink distribution, minimize ghosting, and enhance print quality. Rubber rollers are particularly favored for their flexibility, chemical resistance, and ability to maintain grip over various substrates during high-speed operations.

Rubber rollers are commonly used in offset printing, flexo printing, and gravure printing applications. Their elastomeric surface can be engineered for specific hardness levels (durometers), which ensures compatibility with diverse printing materials like paper, plastic, fabric, and foil. These rollers must also withstand harsh solvents, high temperatures, and continuous pressure—making quality manufacturing and material selection absolutely critical.

Why Printing Rollers Matter in Industrial Applications

In high-throughput manufacturing environments, precision and repeatability are non-negotiable. The industrial roller used in printing must deliver high performance under pressure, ensuring tight tolerances and consistent outcomes. Any compromise in roller design or quality can lead to misalignment, ink buildup, uneven impressions, or frequent downtime.

Printing rollers facilitate the following essential industrial processes:

- Ink transfer from ink wells to plates or substrates

- Uniform coating of adhesives or laminates

- Web guiding, tension control, and alignment

- Rewinding or slitting of printed materials

- Finishing and post-print treatment

Their consistent performance helps minimize material waste, reduce maintenance cycles, and ensure final product quality—which directly affects your bottom line.

Roller Hardness and Load Capacity

Calender rollers must withstand significant mechanical pressure during operation. The roller’s hardness should be selected based on the material being processed and the degree of compression required. For example, soft materials may benefit from a slightly softer rubber-coated roller, while hard materials demand highly rigid and dense rollers.

The hardness rating is usually expressed in Shore A or Rockwell hardness scales, depending on the roller composition. Be sure to specify the operational load and compression requirements when selecting your calender roller to avoid deformation or slippage during production.

Key Materials Used in Manufacturing Printing Rollers

Not all printing rollers are the same. Manufacturers use a variety of rubber compounds and polymers to suit specific industrial needs. Common roller covering materials include:

- Nitrile Rubber (NBR): Offers good resistance to solvents and oils, ideal for general-purpose printing.

- EPDM Rubber: Excellent for UV and ozone resistance, often used in outdoor or high-heat environments.

- Polyurethane (PU): Provides high abrasion resistance and load-bearing capacity.

- Silicone Rubber: Excellent release properties and temperature resistance for specialty coatings.

The roller core may be made of mild steel, stainless steel, or aluminum, depending on the required weight, thermal conductivity, and corrosion resistance.

Factors to Consider When Selecting a Printing Roller

When choosing a printing roller, it’s essential to evaluate multiple parameters to ensure it matches the specific needs of your industrial process. These include:

- Durometer (Hardness): Determines how much pressure the roller can apply without deforming.

- Chemical Compatibility: Resistance to inks, solvents, and cleaning agents used in your process.

- Thermal Stability: Ability to withstand operational heat from high-speed printing.

- Load Capacity: How much mechanical stress the roller can endure during continuous runs.

- Surface Finish: Smooth or textured surfaces can affect ink transfer and coverage.

- Dimensional Accuracy: Roller runout and roundness must meet tight tolerances.

A poor match can lead to inconsistent print results, early roller degradation, and increased maintenance costs.

Applications of Printing Rollers in Industrial Sectors

Printing rollers are essential in a wide range of industries where material surface treatment or ink transfer is required. Some of the most common industrial applications include:

- Packaging Industry: Used in printing labels, cartons, and flexible films.

- Textile Printing: For dyeing, coating, and finishing fabrics.

- Plastic Film Production: For gravure or flexographic printing on BOPP, PET, PVC, etc.

- Paper and Pulp Industry: To print on kraft paper, coated paper, and recycled stock.

- Metal Foil Printing: Involved in foil stamping, lamination, and embossing processes.

The versatility of these rollers makes them indispensable in continuous and batch production lines alike.

Importance of Regular Maintenance and Re-Coating

Like any high-use mechanical component, printing rollers experience surface wear, swelling, or glazing over time. Regular inspection and re-coating are essential to prolong roller life and maintain print quality. This includes checking for:

- Surface cracks

- Swelling or hardening

- Ink buildup or chemical residue

- Uneven wear patterns

Timely re-coating with high-quality rubber compounds can restore performance at a fraction of the cost of new rollers.

Siva Rollers – Best Printing Roller Manufacturer in Ahmedabad, India

If you are searching for a reliable source for industrial-grade printing rubber rollers, Siva Rollers stands as one of the top names in Ahmedabad, India. With years of expertise in designing and manufacturing customized printing rollers for diverse industrial applications, Siva Rollers delivers quality, precision, and performance.

Each roller manufactured by Siva Rollers undergoes rigorous testing and quality control, ensuring resistance to abrasion, chemical exposure, and mechanical stress. Whether you need custom durometer ratings, solvent-resistant coatings, or high-speed roller balancing—Siva Rollers provides tailored solutions to meet your exact industrial requirements.

Future of Printing Rollers in Industrial Automation

As industrial printing shifts toward smart automation, the role of printing rollers is also evolving. With machine vision systems, AI-based defect detection, and precision printing becoming standard, roller design must accommodate tighter tolerances and smarter materials.

Innovations like anti-static roller coatings, temperature-sensitive compounds, and self-cleaning roller surfaces are already making waves. Manufacturers now demand rollers that don’t just print but actively contribute to overall process efficiency and data-driven quality control.

Choosing the right roller today means preparing for the needs of tomorrow’s automated production line.

Invest in Quality, Precision, and Performance

The humble printing roller is more than just a rotating cylinder—it’s a precision tool that drives the quality of your print and the efficiency of your plant. Whether you are in packaging, textiles, paper, or plastics, selecting the right printing rubber roller ensures better output, reduced downtime, and a stronger return on investment.

For industrial buyers looking for reliable performance and trusted manufacturing standards, Siva Rollers offers the expertise, materials, and customization required to meet any challenge. Based in Ahmedabad, India, they are the go-to source for high-performance industrial rollers that deliver consistent results under demanding conditions.

FAQs

A printing roller transfers ink or coating evenly onto a substrate in high-speed industrial printing operations. It ensures precision, alignment, and consistent print quality across large production volumes.

Printing rubber rollers are typically made from synthetic rubbers like nitrile (NBR), EPDM, polyurethane (PU), and silicone, which are chosen based on ink compatibility, chemical resistance, and hardness requirements.

Common types include inking rollers, offset rollers, gravure rollers, flexographic rollers, and impression rollers. Each type is designed for specific functions such as ink transfer, substrate contact, or web guiding.

Selecting the right roller depends on factors like substrate type, printing speed, ink type, roller hardness (durometer), chemical resistance, and desired print quality. Consulting a specialized manufacturer ensures proper material and design match.

A printing roller is a type of industrial roller specifically used in printing machines, while industrial rollers may include rollers for conveying, laminating, guiding, or coating processes across various industries.

Yes, most printing roller manufacturers offer customization options including roller diameter, length, hardness, rubber type, surface finish, and metal core type to suit industry-specific applications.

Printing rubber rollers are used in packaging, flexible film printing, textiles, paper and pulp, pharmaceuticals, labels, and foil printing industries for consistent and high-speed output.

Roller hardness impacts ink transfer, pressure distribution, and grip. Softer rollers offer better ink absorption, while harder rollers provide sharper prints and are preferred for rigid substrates.

Siva Rollers, based in Ahmedabad, India, is a trusted manufacturer of high-performance printing rollers and industrial rubber rollers, known for quality, customization, and competitive pricing.