Which Rubber Roller is Best for Laminating Machines?

Laminating machines are widely used across packaging, paper, textile, and plastic industries. One of the most critical components of these machines is the rubber roller—a tool that directly impacts the machine’s precision, surface finish, pressure consistency, and overall performance. Choosing the right rubber roller for a laminating machine involves understanding roller materials, hardness, coating, and compatibility with temperature and pressure. This blog explores the best rubber roller types for laminating machines, with a focus on industrial performance and durability.

Understanding the Role of Rubber Roller in Laminating Machines

In laminating systems, rubber rollers serve multiple functions such as applying pressure, generating heat, feeding substrates, and guiding materials. Typically, laminating machines use a pair of rollers—one rubber-coated (for grip and flexibility) and one metal (for heat or pressure application). The rubber roller in this setup ensures uniform bonding between two or more layers (e.g., film and board), maintaining even tension and avoiding air bubbles or creases. As such, any variation in rubber hardness, surface finish, or thermal stability can lead to reduced product quality or equipment wear.

Types of Rubber Rollers Used in Lamination

Not all rubber rollers are equal when it comes to laminating operations. Based on the type of laminating machine (cold or thermal), the substrate being used, and operational conditions, different industrial roller specifications are required.

EPDM Rubber Roller

EPDM (Ethylene Propylene Diene Monomer) is a popular rubber material used for lamination rollers due to its excellent heat resistance and insulation properties. These rollers perform well in environments involving heat and humidity, especially in thermal lamination machines. EPDM also resists ozone and weathering, making it durable under long-running lamination cycles.

Nitrile Rubber Roller (NBR)

Nitrile rubber rollers are suitable for oil and solvent-resistant applications. They are commonly used when laminating films or materials with adhesives or coatings that may react with natural rubbers. Their moderate heat resistance and durability make them ideal for both low-speed and high-pressure lamination.

Silicone Rubber Roller

When extreme heat resistance is required (up to 260°C or more), silicone rubber rollers are the go-to choice. They are frequently used in high-speed, high-temperature lamination lines and in the electronics industry. Silicone rollers offer excellent release properties, so they do not stick to adhesives or coatings, ensuring a clean and consistent finish.

Natural Rubber Roller

Natural rubber is known for its high elasticity and excellent grip, making it ideal for feeding and guiding materials in cold lamination applications. However, it may degrade when exposed to oils, UV light, or high temperatures, so it’s generally used in applications that do not involve high thermal stress.

Polyurethane Rubber Roller (PU Rollers)

PU-coated roller are used when toughness and abrasion resistance are prioritized. They offer higher load-bearing capacity than traditional rubber and are effective in laminating operations where pressure consistency over a longer duration is essential.

Key Factors in Choosing the Best Rubber Roller for Lamination

Rubber Hardness (Durometer)

The hardness of a rubber roller is critical. A lower durometer (softer rubber) is ideal for uneven surfaces or when flexible contact is needed to eliminate gaps or air bubbles. A higher durometer (harder rubber) is suitable when pressure needs to be concentrated and consistent across the width of the substrate. Most laminating rollers fall within the range of 50 to 90 Shore A hardness, depending on the material and machine type.

Temperature Tolerance

Laminating machines often operate under continuous thermal conditions. The selected rubber roller must tolerate high heat without deforming or cracking. For thermal lamination, silicone or EPDM rollers are preferred due to their high thermal resilience.

Chemical Resistance

If adhesives, coatings, or solvents are used during the lamination process, the rubber material must resist chemical degradation. Nitrile and polyurethane are excellent for such environments, maintaining integrity over long production cycles.

Surface Finish and Coating

The finish of the rubber roller affects the bonding quality. A smooth surface ensures better contact and fewer defects. Some rollers come with special non-stick coatings or grinding to maintain high-gloss lamination. These are useful for sensitive materials or where surface clarity is critical, such as in printed packaging or decorative films.

Roller Balancing and Precision Engineering

Proper dynamic balancing and core alignment ensure that the industrial roller does not vibrate at high speed, leading to better lamination and reduced wear on the machine. Precision-ground rollers maintain uniform pressure and minimize thickness variation across the substrate.

Applications and Compatibility

Rubber rollers for laminating machines are used across multiple industries:

- Packaging: To laminate film on boxes or cartons for moisture protection and branding.

- Printing: For gloss or matte lamination over brochures, business cards, and catalogs.

- Textile: In fusing and coating operations.

- Electronics: High-precision film lamination for display and circuit board applications.

- Labeling & Stickers: Ensuring adhesive films are properly bonded without bubbling.

Each application requires a roller tailored for specific temperature, substrate type, speed, and pressure. Customization in terms of size, rubber blend, and surface pattern is common in industrial-grade laminating systems.

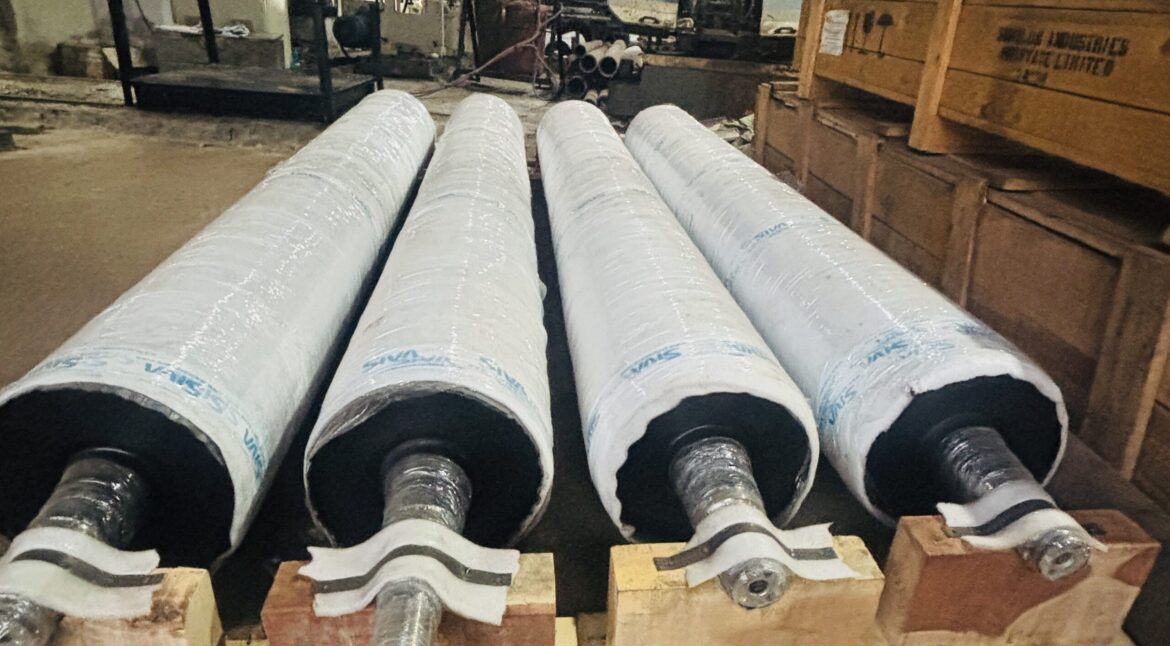

Why Siva Rollers Is the Best Rubber Roller Manufacturer in Ahmedabad, India

When it comes to sourcing high-quality rubber rollers for laminating machines, Siva Rollers stands out as a trusted and experienced manufacturer. Based in Ahmedabad, India, Siva Rollers has earned a reputation for delivering durable, performance-tested rollers that meet international quality standards. Whether you require EPDM, Nitrile, Silicone, or PU-coated rollers, Siva Rollers offers custom-engineered solutions for diverse industrial needs. With advanced CNC grinding, in-house rubber compounding, and dynamic balancing systems, Siva Rollers ensures every roller is crafted for optimal performance and longevity.

Choosing the best rubber roller for your laminating machine depends on several factors—material type, operational heat, speed, substrate compatibility, and machine design. Whether you’re in packaging, printing, or electronics, selecting the right roller can dramatically improve lamination quality, reduce machine downtime, and enhance product output. For industrial buyers looking for precision, consistency, and long-term reliability, investing in high-grade industrial roller is a critical step. And with industry leaders like Siva Rollers, getting the right solution has never been easier.

FAQs

Silicone and EPDM are ideal for thermal lamination, while Nitrile and PU are preferred when chemical resistance is essential. The choice depends on temperature, substrate, and lamination type.

Not always. Cold lamination requires soft, grippy rollers like natural rubber, while hot lamination needs heat-resistant rollers such as silicone or EPDM.

With proper care, industrial-grade rubber rollers can last several months to years, depending on usage, speed, and environmental conditions.

Yes. Regular inspection, cleaning, and re-coating (if needed) help maintain roller performance and extend their lifespan.

You can source custom-engineered, high-durability rubber rollers from Siva Rollers, the leading rubber roller manufacturer based in Ahmedabad, India.