What Is a Calendering Roller? A Complete Guide for Manufacturers

In the world of manufacturing, the precision and finish of products often come down to one essential tool: the calendering roller. From plastics and rubber to textiles and paper, these rollers are vital in enhancing material surface quality, achieving desired thickness, and improving performance. Whether you’re a plant manager, production engineer, or material supplier, understanding calendering rollers can help you optimize your manufacturing process and ensure consistent, high-quality results.

Understanding the Basics of Calendering Rollers

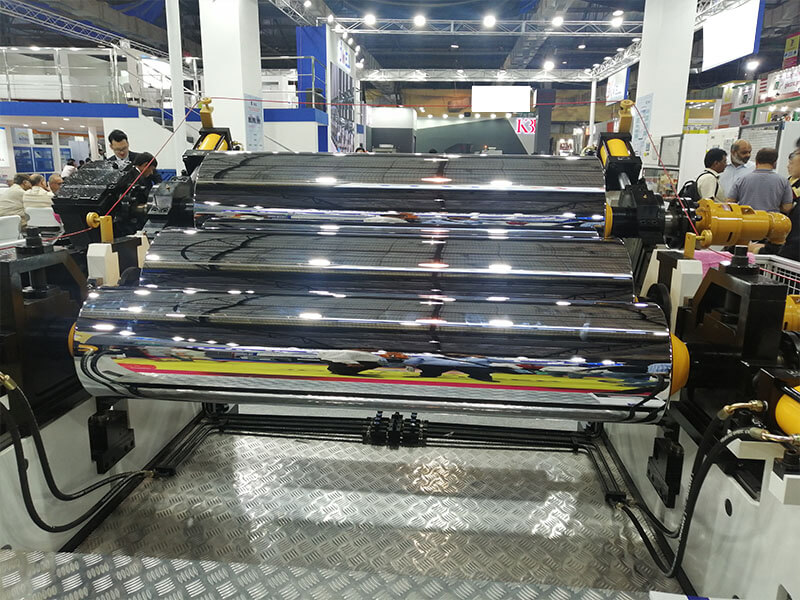

A calendering roller is a high-precision cylindrical tool used in calendering machines to compress and smooth materials such as plastic, rubber, fabric, paper, or metal foils. These rollers are typically arranged in pairs or multiple sets, depending on the desired output. The process involves feeding materials through the gap between rotating rollers under pressure and temperature, resulting in a refined and uniform surface finish.

The primary objective of using calender rollers is to control the material’s thickness and improve surface characteristics like gloss, strength, and texture. These rollers are engineered from durable materials like hardened steel, synthetic rubber, or even chrome-coated metals to withstand high pressure and continuous use in industrial environments.

Role of Calendering Rollers in Modern Manufacturing

In industrial production, consistency and control are critical. Calendering rollers play an integral role in delivering exact results across high-volume operations. They are widely employed in sectors such as:

Their usage ensures that materials have the correct finish, thickness, and dimensional stability before they move to further processing or packaging.

Types of Calendering Rollers Used in Industry

Depending on the end-use and material properties, various types of calender rollers are designed and customized. Some of the most common types include:

- Hard Rollers: Made from steel or iron, used where high pressure is required to flatten and polish materials.

- Soft Rollers: Coated with rubber or polymer to apply moderate pressure, often used in delicate applications like textile or paper.

- Heated Rollers: Fitted with internal heating elements to facilitate the thermal treatment of materials like PVC or rubber.

- Embossing Rollers: Feature engraved surfaces that impart textures or patterns onto materials.

Each of these roller types contributes uniquely to the final product quality, and manufacturers often combine different rollers in a single calendering system for maximum efficiency and precision.

Construction and Engineering of Calender Rollers

The construction of a calendering roller demands meticulous design and engineering. The key components include:

Precision balancing is critical to prevent vibration during high-speed operation, ensuring uniform product finish and extended machine life.

Importance of Surface Finish in Calendering

The surface finish of industrial rollers used in calendering directly impacts the appearance and performance of the processed material. A polished steel roller will impart a glossy finish, while a textured roller can create matte or patterned effects. Maintaining the roller’s surface through regular cleaning and recoating ensures consistent output and prolongs the roller’s operational lifespan.

In high-precision industries like battery separator film production or high-gloss PVC sheets, even microscopic inconsistencies can lead to product rejection. This highlights the importance of high-quality calender rollers in maintaining production standards.

Key Applications Across Industries

Calender rollers are not limited to one industry. Their adaptability and functionality make them essential across a wide range of manufacturing processes:

Each industry demands customized roller solutions based on pressure tolerance, surface treatment, thermal behavior, and overall durability.

Advantages of Using Calendering Rollers in Manufacturing

Incorporating high-quality calendering rollers into your manufacturing process brings numerous benefits:

With the right calendering rollers, manufacturers can significantly enhance production quality and operational efficiency.

Selection Criteria for Calendering Rollers

To keep calendering rollers in top condition, regular maintenance is vital. This includes:

- Material Compatibility: The roller surface should suit the material being processed (e.g., rubber for delicate fabrics, chrome for plastic sheets).

- Pressure and Temperature Tolerance: Depending on the application, rollers must withstand varying operational conditions.

- Roller Diameter and Length: Dimensions must align with machine setup and processing width.

- Surface Finish Requirements: Smooth, textured, or patterned finishes require different roller surface treatments.

- Maintenance and Lifespan: Rollers should be easy to clean, refurbish, and resistant to wear and tear.

These factors not only ensure product quality but also reduce maintenance downtime and extend the equipment’s longevity.

Siva Rollers – Best Calendering Roller Manufacturer in Ahmedabad, India

When it comes to sourcing precision-engineered calendering rollers, Siva Rollers stands out as the leading manufacturer in Ahmedabad, India. With years of expertise and a commitment to innovation, Siva Rollers offers a wide range of calender rollers and industrial rollers tailored to meet the exact requirements of plastic, textile, rubber, and paper industries.

Their products are known for high durability, consistent performance, and custom engineering. Whether you need high-pressure rollers for industrial rubber or heat-resistant rollers for PVC sheet processing, Siva Rollers provides end-to-end solutions that boost your manufacturing productivity and quality.

Maintenance and Care for Calendering Rollers

To keep calendering rollers in top condition, regular maintenance is vital. This includes:

Proper care extends the life of your industrial rollers and keeps your production line running smoothly without unexpected downtime.

Innovations and Future Trends in Calendering Roller Technology

With increasing demand for thinner, stronger, and better-finished materials, calendering roller technology is also evolving. Some notable trends include:

As smart manufacturing and Industry 4.0 practices become mainstream, the role of intelligent and efficient calendering rollers is expected to grow significantly.