The Role of Rubber Coated Rollers in Modern Manufacturing

Rubber coated rollers are an essential component in various industrial and manufacturing processes. From paper production to textile finishing, printing to packaging, these rollers are instrumental in ensuring smooth operation, high-quality output, and durability of equipment. Understanding the role and benefits of rubber coated rollers can help manufacturers enhance efficiency and product quality.

What Are Rubber Coated Rollers?

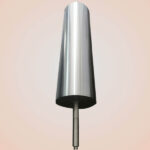

Rubber coated rollers are cylindrical components that are covered with a layer of rubber or elastomer. These rollers are designed to perform specific functions in different industrial applications such as conveying, laminating, squeezing, and printing. The rubber coating on the rollers provides better grip, reduced wear and tear, and protects the materials being processed from damage.

The key advantage of rubber coated rollers is their ability to resist abrasion and provide smooth handling of materials. Additionally, they are customizable to meet specific needs such as hardness, diameter, and surface finish, making them versatile for different types of manufacturing processes.

Applications of Rubber Coated Rollers

Rubber coated rollers are widely used across many industries, including:

Importance of Quality Manufacturing

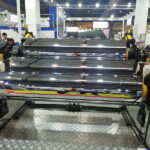

The quality of rubber coated rollers directly affects the output and efficiency of manufacturing processes. This is where choosing the right Rubber Coated Rollers Manufacturer becomes crucial. High-quality rollers, designed with precision and durable rubber coatings, can significantly reduce downtime and maintenance costs while boosting productivity.

When searching for a reliable Rubber Coated Rollers Manufacturer, consider factors such as material quality, customization options, and industry experience. One of the leading names in the industry is Siva Engineering Work, recognized for producing the best rubber coated rollers in India. Their products are known for superior quality, durability, and precision engineering.

Tips for Selecting the Right Rubber Coated Rollers

Future of Rubber Coated Rollers in Manufacturing

With advancements in material science and technology, rubber coated rollers are becoming more efficient and durable. Enhanced rubber formulations and innovative manufacturing techniques are expected to drive the growth of these rollers in modern manufacturing.

As industries evolve, the demand for precision and quality in material handling and processing will continue to grow. Rubber coated rollers, with their versatility and efficiency, are set to play an even bigger role in the manufacturing landscape.

Rubber coated rollers are indispensable in modern manufacturing. Their ability to enhance product quality, increase efficiency, and protect materials is unmatched. Choosing the right Rubber Roller Manufacturer India, like Siva Rollers (Siva Engineering Work) , ensures you get the best in terms of quality and performance. By understanding your needs and selecting the right rollers, you can significantly improve your manufacturing process and output quality.

Whether you are in printing, packaging, or steel processing, investing in high-quality rubber coated rollers is a step towards achieving excellence in manufacturing.